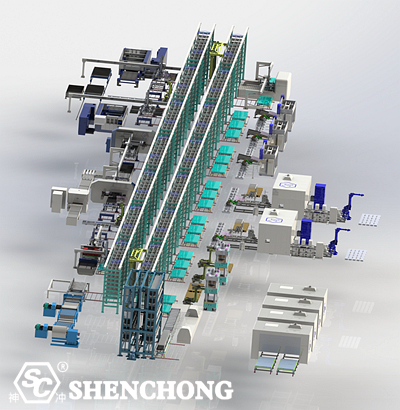

The sheet metal automated production line assembly process is an important means to achieve efficient and precise manufacturing in modern industrial production. Through the integration of automated equipment and systems, sheet metal production lines can automatically complete multiple processes from raw material processing to finished product assembly.

The following are the main links and matters that need to be paid attention to in the assembly process of sheet metal automated production lines.

Inspect and prepare raw materials (such as steel plates, stainless steel plates, aluminum plates, etc.).

Pile raw materials in automatic feeding equipment or storage system according to production requirements.

Ensure that the material size and thickness meet the processing requirements.

Check whether the surface of the raw materials is scratched, oxidized or contaminated.

Use automatic feeding devices (such as vacuum suction cups, roller conveyors) to feed raw materials into cutting or stamping equipment.

Adjust the adsorption or clamping force of the feeding equipment to avoid damaging the thin plate material.

Ensure that the feeding process is smooth without jamming or offset problems.

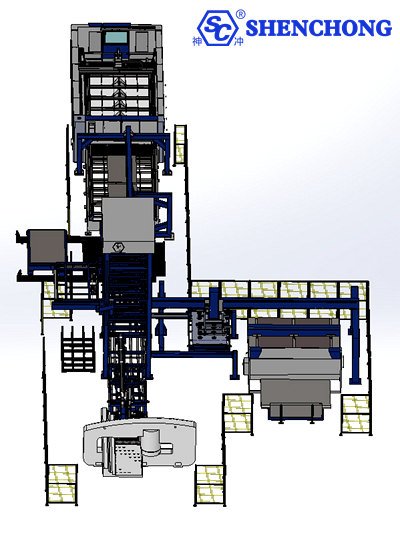

Use a laser cutting machine or CNC punching machine to cut and open the material, and complete the part forming according to the design drawing.

Ensure that the cutting procedure is consistent with the design drawing.

Clean up cutting waste regularly to prevent interference with production.

The cut sheet is transferred to the CNC press brake bending machine, and the bending process is completed through the preset program.

Check whether the bending tool meets the requirements of the workpiece.

Adjust the bending pressure and speed to avoid cracking or deformation of the material.

The welding or assembly of parts is completed by automatic welding equipment (such as robot welding arm) or manual cooperation.

Control the heat input during welding to prevent material deformation or damage to the surface coating.

Check whether the weld is continuous and uniform to meet the design requirements.

Surface treatment (such as spraying, electroplating, polishing, etc.) is performed on the sheet metal parts that have completed preliminary processing.

Ensure that the parameters of the surface treatment equipment meet the material characteristics.

Avoid scratches or contamination during the processing.

Use automatic inspection equipment (such as optical inspection, 3D scanner) to check the size and quality of the parts.

Classify according to qualified and unqualified, and sort to the corresponding area.

Calibrate the testing equipment regularly.

Ensure the sorting equipment moves accurately to prevent misclassification.

Assemble the sheet metal parts through the automated assembly line to form the final product.

Check the connection strength and part position of the assembly process.

Ensure that fasteners, welds, etc. meet the design requirements.

The finished products are packaged by the automatic packaging equipment and then transferred to the storage area.

Ensure that the packaging protection measures are complete to prevent damage during transportation.

Number and record the products when entering the intelligent storage system.

Before starting automated production line assembly, you need to make adequate preparations. This includes determining the assembly environment, preparing the required tools and materials, and checking the integrity of each component. Ensuring that the work area is clean and tidy, the tools are complete, and the components are intact is the first step in the assembly process.

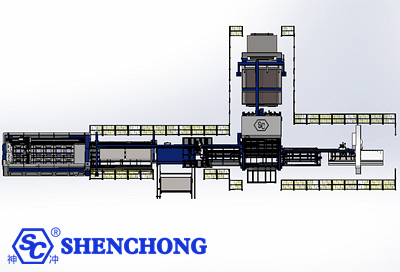

According to the layout of the production line, install the required infrastructure, such as guide rails, brackets, conveyor belts, etc. This step is to ensure the basic stability and accuracy of the production line.

Install all production line equipment according to the design drawings. This includes mechanical equipment, electrical equipment, sensors, pneumatic components, etc. Make sure that each device is installed in the correct position and has enough adjustment space.

According to equipment requirements, connect all necessary lines, including power lines, signal lines, sensor lines, etc. At the same time, the lines should be marked and numbered for subsequent maintenance and management.

According to the production process, write and debug the control program. This usually involves PLC programming, sensor logic, motion control, etc. During the debugging process, the program should be continuously optimized to ensure the stable operation of the production line.

After completing the above steps, a comprehensive test run is performed. This includes single-step test, linkage test and continuous test. If problems are found during the test, adjustments and optimizations are required.

After the test run is completed and confirmed to be correct, the production line can be delivered for use. Before delivery, all relevant documents and technical information should be sorted out for subsequent maintenance and upgrades.

Before sheet metal automated production line assembly, the layout of the production line should be reasonably planned according to the product characteristics and process requirements. Ensure that each device can play its maximum efficiency while reducing the time and cost of material handling.

Use standard parts and modular design as much as possible, which can greatly simplify the installation process and improve efficiency. At the same time, standard parts and modular design are also convenient for subsequent maintenance and upgrades.

The arrangement order of equipment should follow the order of process flow to ensure smooth material flow without crossover or interruption. At the same time, according to the size and characteristics of the equipment, the space should be reasonably used to make the entire production line compact and orderly.

For the parts that need to be linked, ensure the synchronization accuracy between the equipment. This can be achieved by adjusting the parameters and control procedures of the equipment. The higher the synchronization accuracy, the more guaranteed the efficiency and quality of the production line.

During the automated production line assembly process, safety issues should be taken into consideration. For possible sources of danger, protective measures should be taken. For example, install safety doors, protective covers, emergency stop buttons, etc. At the same time, employees should be regularly trained to improve their safety awareness.

During the entire assembly process, document records and management should be done well. This includes design drawings, assembly records, debugging procedures, maintenance records, etc. Perfect document management will help with subsequent maintenance and upgrade work.

Sheet metal automated production lines play an increasingly important role in modern industrial production. They can not only significantly improve production efficiency and reduce human resource costs, but also ensure the consistency of product quality and enhance the market competitiveness of enterprises.

However, to achieve efficient operation of sheet metal automated production lines, enterprises need to do their homework in the early planning and design, equipment selection and integration, software system configuration and debugging, production line assembly and debugging, and pay attention to refined management, skill training and talent training, data-driven decision-making, safe production, and continuous improvement and innovation in actual operation. Only in this way can the advantages of sheet metal automated production lines be fully utilized and strong impetus be injected into the sustainable development of enterprises.

Ensure that the transmission devices between the equipment are smooth without accumulation or interruption.

Set up buffer zones to cope with the differences in processing speeds of different equipment.

Regularly calibrate and check the automated equipment to avoid a decrease in processing accuracy due to equipment errors.

Maintain the equipment lubrication system, electrical circuits and pneumatic components to ensure stable operation.

Equipped with safety devices such as grating protection and emergency stop buttons to prevent accidents.

Regularly train operators to improve safety awareness and equipment operation skills.

Strengthen the quality inspection link, set up online inspection points for key processes, and ensure that products at each stage meet the standards.

Use fully automatic or semi-automatic inspection equipment to improve inspection efficiency and accuracy.

Collect waste generated by cutting, stamping, bending and other links, and classify and recycle them.

Equipped with dust removal and exhaust gas treatment devices to reduce environmental pollution.

Use intelligent production management systems (such as MES) to monitor production status, equipment performance and product quality in real time.

Analyze production data, optimize process flow, and improve production efficiency.

The design of the production line should take into account the needs of product diversification and support rapid switching and adjustment.

Add modular design to enable the production line to have expansion capabilities.

The sheet metal automation production line is a process of continuous optimization. During the assembly process, the plan should be continuously adjusted and improved according to the actual situation to improve the performance and efficiency of the production line. At the same time, we should also pay attention to new technologies and trends in the industry and apply them to the production line.

Sheet metal automation production lines require professional operators and maintenance personnel. After the assembly is completed, employees should be fully trained to familiarize them with the operation and maintenance skills of the production line. At the same time, employees should be encouraged to continue learning and innovating in actual operations.

Sheet metal automation production lines require regular maintenance and care to ensure their stable operation and extend their life. During the assembly process, a reasonable maintenance plan should be formulated and the required spare parts and tools should be prepared. At the same time, a complete maintenance system should be established to ensure that the production line is maintained and maintained in a timely manner.

During the sheet metal automation production line assembly process, the influence of environmental factors should also be taken into account. For example, noise, vibration, temperature, humidity, etc. may affect the performance and accuracy of the production line. Therefore, these factors should be fully considered during the design and installation process, and corresponding measures should be taken to control and manage them.

The assembly process of sheet metal automated production lines requires precise coordination of each process, focusing on equipment calibration, quality control, safety protection and data management. Through reasonable planning and maintenance, automated production lines can significantly improve production efficiency, reduce costs, ensure product quality, and meet the requirements of modern manufacturing for flexibility and environmental protection.