Why do we need a servo CNC hydraulic press brake machine? Against the backdrop of increasingly fierce market competition and increasingly expensive labor costs, the market has increasingly high requirements for efficient, energy-saving, and environmentally friendly sheet metal manufacturing equipment.

Reducing the production and manufacturing costs of products is a problem that enterprises have to face. Energy conservation, consumption reduction, green environmental protection "has become its preferred theme.

The electricity consumption of equipment has become an important part of the production cost of enterprises. Reducing the energy consumption of bending machines has become one of the effective ways for enterprises to reduce costs and improve product competitiveness.

With the continuous development of industrial technology, market competition is becoming increasingly fierce. Due to the barriers in control principles, traditional electro-hydraulic CNC press brake machines have become increasingly prominent in terms of throttling, heating, and high power consumption.

The oil electric hybrid CNC bending machine is equipped with two independent oil tanks. The structure is simple and compact. Easy to clean. Reduce secondary pollution of hydraulic oil.

To achieve efficient and stable bending efficiency, the main cylinder adopts a special speed increasing cylinder structure design. The CNC system drives the oil cylinder through two servo power units and controls the synchronous operation of the bending machine oil cylinder through grating ruler (or magnetic grating ruler) detection and feedback, achieving high-precision machining of the workpiece.

This model has the characteristics of high speed, energy and electricity conservation, low noise and environmental protection.

The structure of the electro-hydraulic synchronous CNC press brake machine is controlled by a regular three-phase asynchronous motor to control a quantitative hydraulic pump. The flow rate through the proportional pressure valve is changed through the throttling of the overflow valve, achieving dual cylinder synchronization and ultimately meeting the accuracy requirements of bending processing. This is called "valve control".

This technology has the drawbacks of high energy loss and excessive heating. The energy loss of the hydraulic system can cause a decrease in the overall efficiency of the bending machine system, an increase in oil temperature, and deterioration of the oil, leading to the failure of the bending machine.

In order to maintain the thermal balance of the oil, the method of increasing the amount of hydraulic oil is usually adopted. At the same time, the problems brought about are the increased cost of waste oil treatment and the potential pollution impact on the environment. Moreover, the noise of the electro-hydraulic synchronous CNC bending machine is relatively high, which can bring certain noise pollution to the surrounding environment.

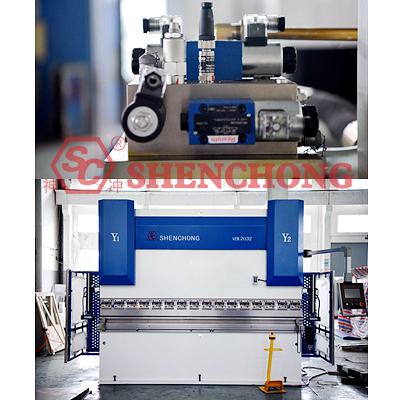

The electric hybrid servo CNC hydraulic press brake machine (pump controlled) system includes a power unit and control valve group connected to the CNC system. The power unit includes a servo motor and a one-way quantitative pump connected to the servo motor, as well as an independent fuel tank. The control valve group includes overflow valve, unloading valve, one-way valve, directional valve, back pressure valve, lifting valve, safety valve, and charging valve.

By controlling the speed of the servo motor of the power unit through a CNC system, the displacement of the oil pump connected to it is controlled, thereby achieving displacement speed control of the actuator (oil cylinder). By setting the torque of the servo motor through the CNC system, the output force of the left and right executing components (cylinders) can be controlled.

The displacement readings of the left and right actuators (cylinders) are fed back to the CNC system through displacement sensors (grating or magnetic grating). After comparing the CNC system, the left and right power units are controlled to achieve closed-loop control of synchronization and positioning of the left and right executive components (cylinders). The displacement sensor constitutes an internal feedback link to improve the control accuracy of the system.

After multiple tests, we found that under the condition of operating the equipment at 90% load for 2 hours:

① Efficient: Efficiency increased by 30%~50%.

② Energy-saving: Energy saving increased by 28% to 54%.

③ Accuracy: The Y-axis walking error is small, and the accuracy at any position is increased by an average of 5 times.

④ Low noise: The noise is reduced by 10-12 dB, greatly optimizing the working environment.

⑤ Environmental protection: Reduce hydraulic oil volume by 50%~80%.

⑥ Temperature control: The oil temperature control is superior, which is conducive to the operation of the entire machine.

Through the comparison of the two control methods mentioned above, we can clearly see that the electric hybrid servo CNC (pump control) system has the characteristics of high efficiency, energy conservation, low noise, and environmental protection. The servo cnc hydraulic press brake machine has better synchronization and is truly energy-saving and efficient. Simple structure and faster speed.

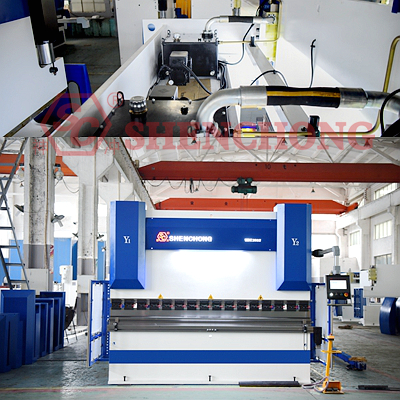

With the accumulation of more and more application experience, technological improvement, and optimization, the electric hybrid servo CNC press brake machine produced by Wuxi Shenchong Forging Machine Co., Ltd. has been widely used in sheet metal production and manufacturing enterprises, mainly serving industries such as shipbuilding, rail transit, electrical switch cabinets, building decoration, and 5G communication.

The servo cnc hydraulic press brake belongs to energy-saving and environmentally friendly products. Its technological superiority has been fully reflected in practical production applications, which not only responds to the call of the country to build an energy-saving and environmentally friendly green social environment, but also meets the increasingly high precision and efficient production needs of enterprises. It is highly praised by users, and there is a trend to partially replace traditional digital controlled bending machines in the future, with a very broad market prospect.