The CNC plate bending machine adopts popular construction, has well rigidity, beautiful shape, advanced technology and reliable performance. So it is one of the ideal sheet forming equipment.

It is widely used in industries of aircraft, automobile, shipbuilding, electrical appliances, light industries and so on. High productivity and long life are two of its virtues.

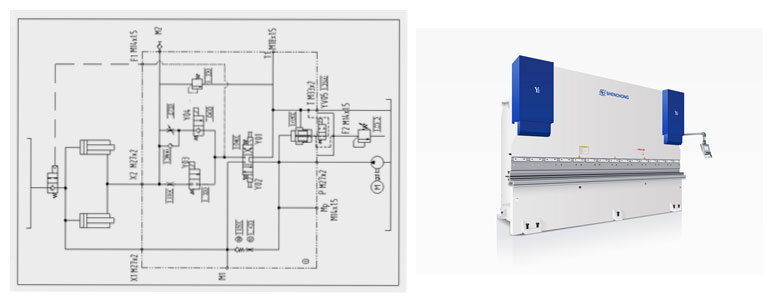

A hydraulic driving system is used in the machine. Its working principle is as follows:

The motor runs in a direction as indicated by the arrow on the pump (clockwise). To drive the oil pump, which draws the filtered oil into the valves through the valve block, seals the oil in the lower chamber of cylinder, holding the ram in any desired position. At the same moment, the pump stops working through the valve [1.0400].

(Hydraulic Diagram)

When solenoids Y02 and Y03, Y04, Y05 start to work, the oil in the lower chamfer of cylinder is drawn to the tank through valves [1.0600] and [1.0400] , the ram will move downward fast for its own weight.

At the same time, the upper chamber of the cylinder is filled with the oil both from the oil pump output and the oil-charge valve. The ram moving speed is controlled by orifice [1.0700].

When the ram moving down to the speed-alternate position, ( it carried out by the limiting switch and the stopper nuts ), solenoids Y02, Y03 and Y05are activated. The oil enters the oil cylinder and the ram advances at working speed, which can be controlled through valve [1.1100]. The working stroke length is controlled by the adjustable potentiometer.

Solenoids [1.0400] are required to be not activated, so as to allow a pressure release. Then solenoid Y01, Y05are activated and the ram returns at a constant speed.

The desired pressure can be obtained by adjusting long-distance tonnage control valve [1.0310]. The pressure in the hydraulic system can be read off from pressure gauge M1.,and the pressure set up by press brake manufacturer is 25 Mpa (nominal pressure) which ensure that the pressure is within the rated pressure of the machine to prevent possible damage to the machine due to the overload.

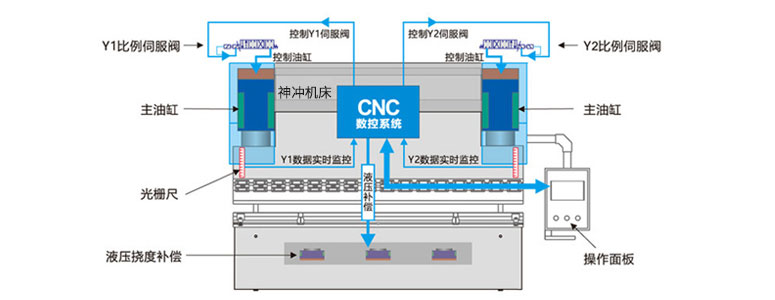

Fully CNC bending machine machine is an electro-hydraulic synchronous system, which uses raster ruler and servo proportional valve to control the synchronization of the slider.

This model has a higher configuration and is mostly used for large-scale bending machines and equipment with higher bending accuracy requirements.

Economical CNC plate bending machine is to control the back gauge and slider stroke. You can enter the work piece detail size you want to bend, and then enter the bending angle of each step. Just find out the program when you use it. The bending machine will adjust the back gauge distance and bending angle according to the steps you input.

CNC Hydraulic Press Brake Machine For Sale

(CNC Electro-hydraulic Circuit )

Turn the hand wheel to fine-tune the distance of the slider at the bottom dead center, adjust the angle value of the workpiece, remove the right joint and turn the handwheel. It can adjust the parallelism between the bottom dead point slide and the work table surface, correct left and right. The angle difference between the two sides of the workpiece.

It is used to adjust the pressure of the machine, the maximum pressure can be seen from the pressure gauge.

When the slider is at the lower limit, the reading value is displayed by the revolution meter, and the reading is 0.1 mm.

With start, indicator light, emergency stop, potentiometer, changeover switch, etc.

It is used to control the length of the working stroke, and can also control the holding time of the work piece.