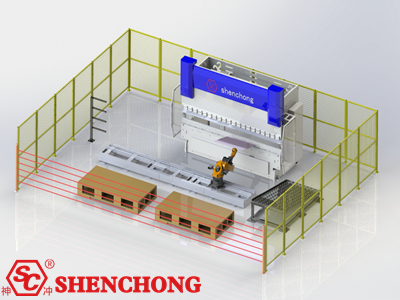

Shenchong robotic press brake plate bending production line realizes unmanned sheet metal bending.

CNC hydraulic press brake configured 6+1 or more equipped with a 6-axis or 7-axis robot form a fully automatic bending cell. Automatic bending flexible line solution provides stable quality sheet metal forming, making your production more cost-effective.

Intelligent Manufacturing Redefine Your Future!

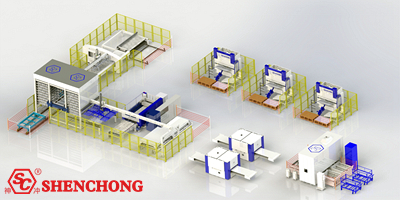

Transform and optimize the bending production according to the customer's original equipment. Also, provide customers with a complete new sheet metal flexible bending solution.

- High tech, high performance

- Maximum bending flexibility

- Increase productivity and efficiency

- Save labor cost and material loss

- Reduce operation error

- Better machining accuracy and consistency

- Achieve high quality mass production

- Promote the working environment

- Reduce labor intensity and safety in production

- Improve the corporate image for the long-term development

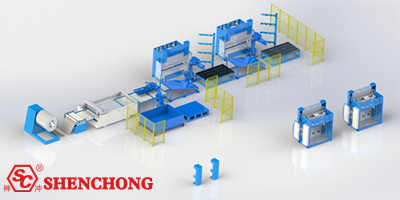

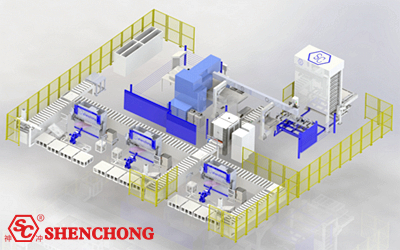

Plate bending production line can be combined with other CNC machine tools and automatic production system to form complete flexible lines.

- Unlimited creativity: the cooperation and link between robot and CNC bending machine eliminates the limitation of bending feasibility.

- The robot bending cell connect with the sheet metal storage system.

- Communicate with industrial MES system to realize continuous unmanned production.

- Full automatic bending production line control software automatically optimizes the production sequence and guides the operators to make the work easier and reduce the risk of error.

Q: How to get an accurate robotic plate bending production price from SHENCHONG?

A: Every customer can get robotic bending production line price from us. Please provide us the details of your sheet material, max thickness and max width, what kind of machine do you want to connect. Shenchong auto bending cell can not only connect with laser cutting machine and turret punch press, but also it can connect with any other sheet metal processing machine. We have our own engineer team to design the technical propsal for you. Also, it is best to provide us your factory site space, and we will try best to design the most suitable technical proposal for you.

Q: What's the shipping cost from China to your country?

A: We can send machine to your port or door address by sea or railway. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery. SHENCHONG is a professional sheet metal bending designer, we will provide the best shipping proposal.

Q: Do you offer teaching & training?

A: Yes, after our engineers install and adjust the robot bending production line, they will also teach your workers how to operate the machine and how to do the daily maintenance.

Q: Do you offer after sales service?

A: Yes, during the guarantee period, Shenchong responds within 60 minutes after receiving the customer's failure notice. If the on-site service is required, we appoint professional and technical personnel to provide services such as consulting, maintenance and replacement of parts, and timely fill in the maintenance report (including the maintenance report (including the maintenance report (including The cause of failure, treatment and buyer's opinions, etc.).

SHENCHONG will remotely guide the customers in the maintenance and repair of all equipment and software of the project at the 6th and 12th months after the completion of project delivery.