With the continuous development of industry, the consumption of sheet metal parts is also increasing. How to improve the production efficiency of small batches and multiple varieties, and make them intelligent is crucial.

As a result, more and more people are aware of the automated production line for sheet metal. Here is a Laser Cutting Automatic Production Case we have designede for our clients.

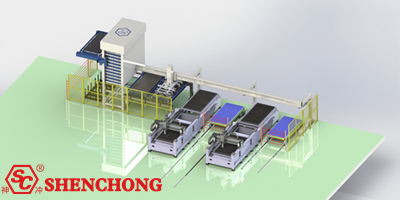

The customer needs a set of sheet metal intelligent storage system and two laser cutting machines. The following is technical solution:

The 3015 sheet metal warehouse has ten floors, of which eight are used for storage and two are used for post discharge. Each layer stores 3 tons of material.

Both laser cutting machines are 3015 model. The cutting power is 6000 watts and 3000 watts respectively.

The tabletops are all exchange platforms, and the guide rails of the low platform are lower than those of the high platform, making it impossible to carry forks and cut materials.

The 6000 watt laser cutting machine generally cuts 4-10 millimeters of sheet metal. A 3000 watt laser cutting machine cuts 1-3 millimeters of sheet metal.

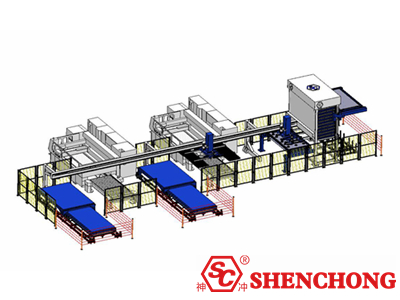

The sheet is stored in 8 layers. The 4-6 mm plate is lowered to the second to last layer of the material warehouse and walked to the loading station 2 behind the material warehouse.

Lower the 1-3 mm board to the bottom layer of the material warehouse and walk to the loading station 1 at the back of the material warehouse.

The vacuum suction cup travels to the 6000 watt laser cutting machine, picks up the cut thick plate and places it in the unloading station 2, and then in the loading station 2, picks up 4-6 mm plates and places them on the 6000 watt cutting machine. This completes the loading and unloading process of a 6000 watt laser cutting machine.

The truss suction cup then travels to the position of the 3000 watt laser cutting machine and descends above the 3000 watt laser cutting machine. Use a vacuum disc to suck up the sheet and place it on the unloading station 1.

Go to the top of workstation 1 and pick up a board for shaking and splitting, and measure the thickness. Then, place the sheet on a 3000 watt laser cutting machine. Thus, two laser cutting machines can automatically process.

- Using an automatic three-dimensional material warehouse to store sheets. Save the usage area of factory premises.

- Adopting an intelligent management system to quickly grasp the inventory status of sheet metal in real-time.

- One click start. Automated operation.

- Large capacity storage tower. Safe and fast operation.

- Professional team design is suitable for most factory workshops.

- The feeding tray automatically completes incoming and outgoing materials. Accurate positioning and automatic locking.

- Improve work efficiency. Reduce the risk of injury. Reduce the labor intensity of staff.

- Customer satisfaction with automated production sites has increased.

- Implement "6S" management on site. The work site is clean and orderly, making it easy for customers to visit.

-Safety overrun control: If the single-layer weight limit is exceeded, the weighing system will automatically alarm.

- Safety protection: The light curtain guardrail enhances the safety capability of the entire production line.

The sheet metal laser cutting automated storage system provides personalized customization solutions to meet your production system needs.

No matter how large or small your business scale is, we will wholeheartedly cooperate with you! No matter how complex your processing process or production process is, we will come up with the most suitable solution for you!