The correct operations can improve hydraulic metal press brake working efficiency, save costs, and also the machine can be durable.

We will give you some useful tips for press brake machine operation.

– Only trained workers can operate the bending machine.

– Operators should read the manual carefully.

– Make sure that you have an understanding of the details of the hydraulic metal press brake, structure, performance and safety information before starting use.

– Follow the item of safety information before starting to use the hydraulic sheet metal press brake machine.

– Press brake operations manual is very important. We need to keep the manual properly for check when necessary.

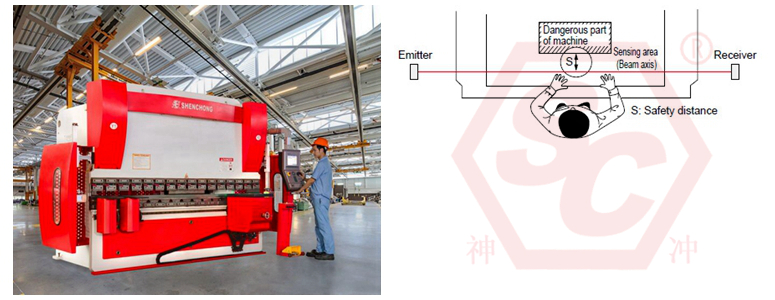

Hydraulic press brake machines are widely used in the manufacturing industries of aircraft, automobile, shipbuilding, electrical appliance, machinery and light industry.

So correct operation and easy use are very important. When using machine, there are some tips as follows.

Machine frame:

– Operators should often check all connecting bolts and pipe joints to ensure they are tightened before operation.

– The main parts of the machine such as frame are all of welded structure.

– When using a hydraulic metal press brake, the operator should often check the welding line during operation.

– Stop the machine immediately if the crack is found, and only be repaired by skilled person before operation again.

– Must make sure that metal hydraulic press brake machine is grounded reliably.

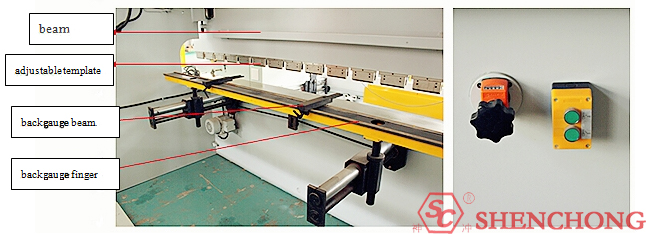

Back gauge:

– CNC sheet metal press brake back gauge is driven by servo motor, can achieve precise positioning.

– SHENCHONG cnc hydraulic press brake machine back gauge is with imported famous brand, also the back gauge can be adjusted finely by manual.

– We need to check periodically the gap between guide screw and nut, refasten again or replace the worn parts when the gap too big to guarantee an accurate positioning.

– Operators are forbidden to adjust back gauge stop fingers in front of themachine.

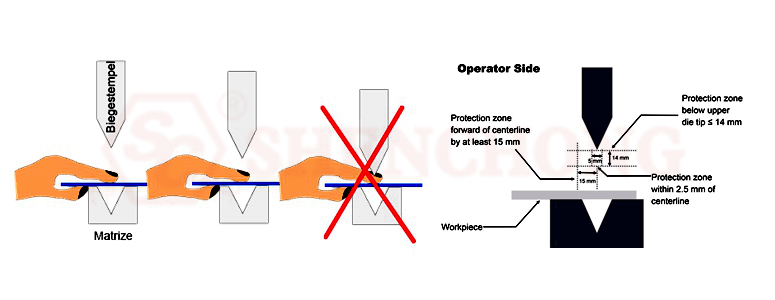

Top and bottom dies operation:

– When using the hydraulic sheet metal brake press machine, we will bend different material, different plate thickness, plate width and length.

– So top tool and bottom dies of must be correctly selected.

– When the thickness of the plate is changed, we need to reselect the lower die’s opening width.

– When bending short work pieces, operators should put the plate in the middle of the machine to avoid unbalanced load.

– We often need to adjust and change the opening of bottom die, this time we can use lifting ring to turn or move the bottom die, to select correct V – groove on hydraulic metal press brake dies.

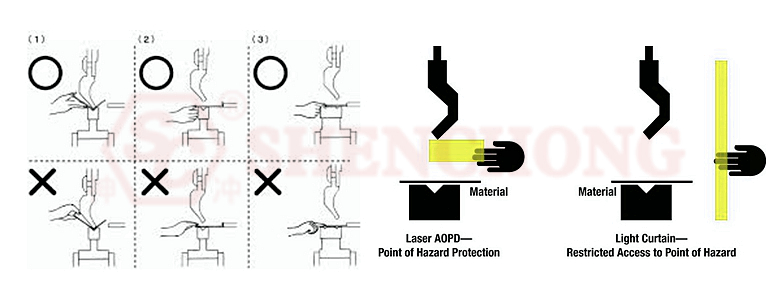

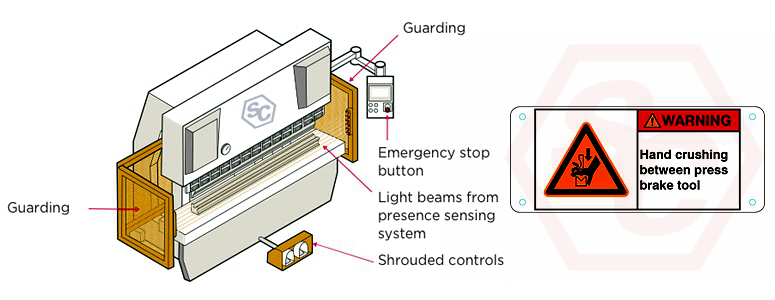

Safety:

– Never make the hydraulic sheet metal press brake machine running under bending force exceeding nominal force, avoid the damage of the machine in any case.

– At all time, don’t put your hands or any parts of your body into the dies area anytime,

– And never adjust any part behind the ram across die area from the front of the machine.

– We should keep the body away from the workpiece to avoid injury caused by the workpiece bending when the machine is running.

– The ram must stay at bottom dead center when the hydraulic metal press brake machine stops working.

Power:

To ensure the stability of power supply, we must note points as follows during the hydraulic press brake machine operation:

– Operators can not welding on machine nor connect high power.

– We can not use them for earthling conductor.

– Ensure that the high power point of the machine is stable with no high-voltage circuit.

Operation environment:

– The hydraulic CNC press brake machine should be installed in the work shop without direct sunlight.

– For hydraulic sheet metal press brake machine operation environment, it is better to be with low humidity, less dust and good ventilation.

Hydraulic and compensation system:

– Before using the hydraulic metal press brake, we need to confirm whether hydraulic system can prevent the machine when machine bending pressure overload.

SHENCHONG cnc sheet metal press brake machines are all with electro-hydraulic proportional valves, which are imported from Germany or other European countries.

Therefore, SHENCHONG hydraulic press brake machine can give warnings at the first time when overload.

– We should operate the machine within a rated pressure range, otherwise serious accidents may occur.

– Compensation system under the hydraulic press brake bottom dies can ensure a higher bending accuracy.

– When we buy a bending machine, it’s best to choose the machine with compensation. SHENCHONG metal press brake machines are usually with the compensation system.