The widespread application of laser cutting processing technology has become a trend. Many industries require the use of fiber laser cutting machines. So how to choose a cutting fiber laser?

In order to avoid problems in practical applications, the following performance issues must be considered before buying laser cutting processing equipment: low failure rate, high stability, low comprehensive use cost, long service life, laser safety, small size and light weight, etc.

Starting from the 3 keys and 7 principles for selecting fiber lasers for CNC laser cutting machines, Wuxi Shenchong will introduce in detail how to choose fiber lasers.

If it is used for cutting metal, the laser power should be at least 200W or above, or a kilowatt level laser should be used.

Generally, laser cutting machine manufacturers will choose imported continuous light lasers. If used for cutting non-metals, the laser is mainly composed of pulsed light lasers below 50W.

Fiber lasers are commonly used in XP and 2000 systems. The difference between the two is not significant.

Laser cutting machine protective lenses, also known as laser cutting machine focusing lenses. The focusing lens of a laser cutting machine is a relatively precise optical element.

Optical lenses are important for laser cutting machines. Its cleanliness directly affects the processing performance and quality of laser cutting machines.

Improper selection of optical lenses can cause significant laser loss, frequent damage, unstable product quality, and serious losses to enterprises. Although the protective lenses of laser cutting machines are vulnerable parts, in order to improve their utilization rate and reduce production costs, they can be cleaned regularly to achieve the goal of reuse.

Laser Cutting Automatic Loading and Unloading System

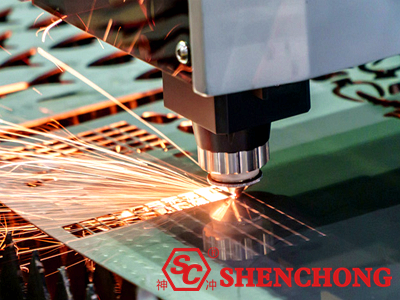

Laser beam is an important performance that provides processing quality. There are three important indicators for the beam quality of fiber laser.

This is an important indicator for describing the quality of laser beams. The smaller the BBP value, the smaller the beam can be focused, resulting in a higher power density. The speed of sheet cutting will be faster. The smoothness of the cutting surface will be higher.

Meanwhile, the smaller the BPP, the more likely it is to cut high reflective materials such as copper and aluminum. Improve the production efficiency, quality, and application range of cutting.

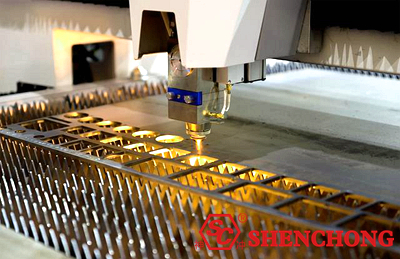

The roundness of the light spot describes the uniformity of energy distribution in different directions of the light spot. The energy distribution of high circularity light spots in all directions is uniform.

When doing non linear cutting, it can ensure the consistency of the cutting surface smoothness and cutting speed in all directions, ensuring the quality of the cutting product.

The higher the circularity, uniformity, and concentration of the energy distribution of the light spot, or the closer it is to the Gaussian distribution, the higher the central energy of the focused light spot, and the better the symmetry of the light spot.

When cutting, the "blade" of the fiber laser becomes sharper, resulting in faster sheet cutting speed and better cutting surface smoothness. And the consistency of the anisotropic slits is higher.

The spot energy distribution of IPG cutting fiber laser is close to Gaussian distribution. The consistency of cleanliness and cutting speed ensures the quality of cutting products.

Output power stability is an important performance indicator for providing processing quality. It describes the stability of laser output power in the full power range (10% -100%) under different output powers and long-term use.

Full power range output power stability:

The lower the stability value, the better the stability of the laser under different output powers.

It can ensure the consistency of cutting surface smoothness and cutting speed when cutting with different thicknesses. It can improve the quality of the cut products and ensure the stability of the cut product quality.

Quality control of core components is an important indicator for reducing equipment failure rates. The core components determine the overall performance and quality of the laser.

Outsourcing core components can make it difficult to control the overall performance and quality of the laser, that is, the performance and quality of the laser cutting machine are uncontrollable.

The lifespan of core components affects the failure rate and service life of cutting fiber lasers. The higher lifespan of core components results in a low failure rate and long service life of the laser, reducing customer downtime and maintenance costs.

The redundant hot standby design of the laser module can activate the hot standby function in the event of a partial power module failure of the laser.

Replacing the faulty power module with backup power ensures that the laser cutting machine can continue to operate normally. Reduce customer downtime costs caused by partial power module failures.

When the temperature of the laser cooling system and the cooled components is lower than the dew point temperature of the surrounding humid air, condensation can occur, leading to device corrosion and failure.

The dehumidification device effectively reduces the internal environmental humidity of the laser, avoids condensation caused by high humidity, and reduces damage to the circuit board and power module caused by condensation. Reduce laser failure rate, reduce customer laser maintenance costs and downtime costs.

The protection level of the laser cabinet describes the level of waterproofing and dust prevention in the cabinet.

High IP level cabinets can effectively prevent external dust and water from entering the cabinets. Keep the interior of the cutting fiber laser cabinet clean and dry to avoid laser malfunctions caused by dust and water entering the cabinet.

Electro-optical conversion efficiency is an important performance in reducing operating costs, describing the proportion of power input converted into output power.

High electro-optical conversion efficiency, low power consumption at a certain output power, and low heat generation of the laser. Reduce the power consumption cost of customers' lasers and the power consumption cost of water chillers required for heat dissipation.

- Russia IPG world-renowned high-performance fiber laser and amplifier.

- German SPI continuous fiber laser and ns pulse fiber laser.

- German JENOPTIK semiconductor lasers and solid-state lasers.

- American COHERENT CO2 laser, semiconductor laser, argon/krypton ion laser, and pulsed dye laser.

- China Raycus pulse fiber laser.