The sheet metal industry often encounters CNC machine tools and CNC lathe machines. What is the difference between CNC machine tools and CNC lathe machine?

First of all, let's understand what is CNC machine tools and what is CNC lathe machine.

The machine tool is a machine that processes metal blank into machine parts. It is a machine that manufactures machines, so it is also called "work parent machine" or "tool machine", which is used to referred to as machine tools.

There are many ways to process mechanical parts in modern machinery manufacturing: in addition to cutting, there are also casting, forging, welding, stamping, squeezing, etc.

CNC machine tools are the abbreviation of digital control machine tools and are automated machine tools equipped with program control systems.

This control system can logically processing procedures with control codes or other symbols, and use the decoding code to make the machine tool movement and process the control unit of the parts. The operation and monitoring of CNC machine tools are completed in this CNC unit. It is the brain of CNC machine tools.

SHENCHONG Forging Machine Tool Co., Ltd. is a company specializing in sheet metal CNC machine tools. It specializes in production of CNC press brake, CNC shearing machines and CNC rolling machines.

1) High processing accuracy and stable processing quality.

2) Multi -coordinate linkage can be performed to process parts with complex shapes.

3) When the processing parts change, it is generally only necessary to change the CNC program, which can save the production preparation time.

4) High accuracy and rigidity of the machine tool itself, can choose favorable processing, high productivity (generally 3 ~ 5 times that of ordinary machine tools).

5) High degree of automation of machine tools can reduce labor intensity.

The lathe is a machine tool that mainly uses the rotating work piece to use the rotating work piece. There can also be corresponding processing on the lathe with drill bit, expansion drills, re -cuttings, taps, plate teeth and flower rolling tools. The lathe is mainly used for processing shafts, disks, sets, and other work pieces with rotation surfaces. It is the most widely used machine tool in mechanical manufacturing and repair factories.

1) CNC lathes can process complex work pieces such as oblique cylindrical, arcs, grooves, and worms. It has many compensation functions, including linear interpolation and arc interpolation, which has played a good economic effect among complex parts of mass production.

2) CNC lathes and turning centers are high-precision and highly efficient automated machine tools. Equipped with a multi station turntable or power turntable, it has a wide range of processing performance. CNC machine tools automatically process parts based on pre programmed machining programs.

3) The machining process route, process parameters, tool trajectory, displacement, cutting parameters, and auxiliary functions such as tool change, spindle forward and reverse rotation, and cutting fluid switch are compiled into a machining program table according to the instruction code and program format specified by the CNC machine tool. The content of the program table is then recorded on the controlled medium and input into the CNC device to process the part.

4) CNC programming is the entire process from part drawing analysis to control production. The difference between CNC machine tools and ordinary machine tools is that CNC machine tools automatically process parts according to programs, while ordinary machine tools are manually operated by humans. To achieve different processed parts, you only need to change the automatic program that controls the machine tool. CNC machine tools are suitable for processing small batches of parts with complex shapes or high accuracy.

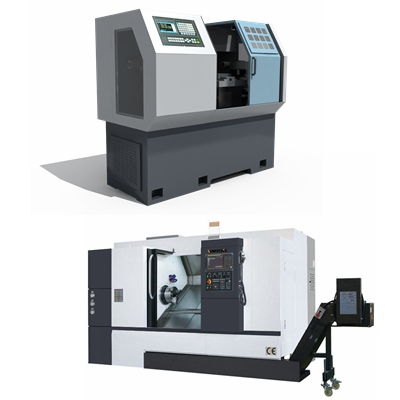

CNC machine tools and CNC lathes are two different types of machine tools. The main difference between them is the difference in use and structure. How to distinguish CNC machine tools and CNC lathes?

CNC machine tool: refers to a machine that uses a CNC system to process mechanical parts. CNC machine tools can perform multi coordinate linkage and are suitable for processing various shapes, surfaces, materials, and sizes of parts, and can achieve efficient, accurate, and diverse processing according to different processing requirements. CNC machine tools effectively solve complex, precise, small batch, and multi variety parts processing problems, and are a flexible and efficient automated machine tool.

CNC lathe machine: refers to a machine that uses a CNC system to perform turning processing on shaft parts. CNC lathes are usually used to process the inner and outer circles, conical surfaces, threads, etc. of shaft parts, and can achieve efficient, accurate, and diversified processing according to different processing requirements.

To distinguish the CNC machine tool and CNC lathe, you can distinguish according to their main use and structural characteristics. If you want to process axis parts, you can use CNC lathes. If you want to process other types of parts, you can use CNC machine tools.

Processing accuracy: Both CNC machine tools and CNC lathes have high processing accuracy, but due to the specialized use of CNC lathes for machining shaft parts, their accuracy in processing shaft products is usually higher than that of CNC machine tools. However, compared to CNC lathes, CNC machine tools have a higher degree of flexibility, with a processing accuracy of 0.05-0.1mm, stable and reliable processing quality. When processing the same batch of products, the consistency of the products is good, and the yield is stable and reliable.

Processing efficiency: The processing efficiency of CNC machine tools and CNC lathe machine depends on various factors, such as equipment specifications, processing requirements, operating skills, etc. It is more suitable to use CNC lathe machine to process products such as inner and outer circles, conical surfaces, and threads. If encountering multi sided shapes and non-standard products, using CNC machine tools will be more efficient. Overall, as long as the process is selected correctly, both CNC machine tools and CNC lathe machine have high processing efficiency.

Processing process: CNC machine tools and CNC lathe machine have basically the same process, which involves program input, editing, part loading and unloading, tool preparation, observation of machining status, and part inspection. The labor intensity is low, and the only difference is that the loading and unloading positions of the parts are different.