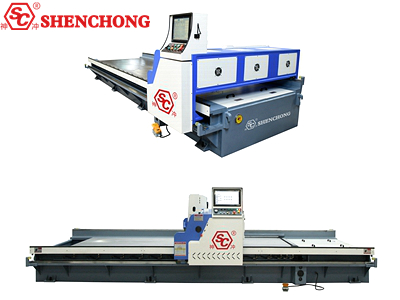

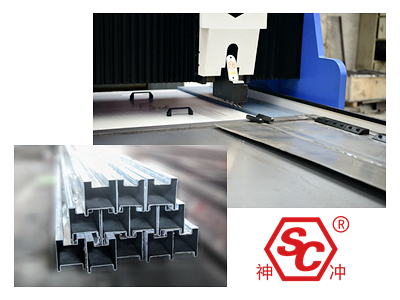

V groove is a sheet metal processing process, that is, V-shaped slotting is performed on the sheet metal. The CNC v groove machine was born for this process.

V grooving machines are widely used in stainless steel processing, building decoration, kitchen utensils, door industry, elevator manufacturing and other industries.

It is necessary for users of cnc stainless steel v groove machine to understand the operation instructions, functions and structures of the machine tool. It is forbidden to use super functions.

Now let's talk about the operation rules of the CNC grooving machine.

First of all, the inspection of the steel groove machine can be divided into daily inspection and special inspection.

The daily inspection is mainly to check the general parts of the machine tool. This is to deal with and check the faults occurred during the operation of the machine tool, and it is carried out by the operator. Special inspection refers to periodic inspection of key parts and important parts of the machine tool.

What inspection work should be done before using the CNC v grooving machine? As follow:

It mainly includes the following aspects:

First, how many maintenance points are there for the stainless steel v groove machine. Scientific analysis equipment. Find out where the fault may occur. Check these maintenance points and you can find faults in time.

Standards for calibration, temperature rise, pressure, flow and tightness shall be formulated one by one. There should be clear gauges. As long as it does not exceed the standard, it will be regarded as failure.

Conduct routine inspection once. Determine the inspection period. Sometimes check once a week. Sometimes it is checked once a month. Determine according to the situation.

There should also be clear regulations on which items to check for each maintenance. You can check one or several.

- Before starting the grooving machine, check whether all parts of the machine tool are complete and normal according to the equipment inspection rules. Whether the safety protection equipment of the machine tool is reliable.

- Add lubricating oil according to lubricating point rules. Check whether the oil pointer, oil quantity, oil quality and oil circuit are normal. Keep the lubrication system clean. The oil tank and oil hole shall be closed.

- It is necessary for the operator to operate in strict accordance with the regulations of the CNC v groove machine. Do not operate the equipment without permission of management personnel.

- Press each key with appropriate force. Do not hit the keyboard, keys and display screen with force.

- No other items shall be placed on the work table.

- In case of any fault or abnormal phenomenon of the machine tool, stop the machine immediately to check and eliminate the fault.

- The operator should stop the machine when leaving the machine tool, changing the speed, changing the tool, measuring the size and adjusting the workpiece.

- After the operation, keep all parts of the machine tool in the original state and cut off the power supply.

- Keep the machine tool accessories properly. Keep the machine tool neat and intact.

- Clean the machine tool well. Keep clean. Carefully carry out shift handover procedures. Fill in the shift handover record.

Finally, Wuxi Shenchong remind you that keeping in mind the stainless steel v groove machine operating procedures and putting safety in production first.