A CNC punching machine is a stamping press. In industrial production, compared with traditional mechanical processing, stamping process has the advantages of saving materials and energy, high efficiency, low technical requirements for operators, and the ability to produce products that cannot be achieved by mechanical processing through various mold applications. Its use is more and more extensive.

Since the CNC punching machine adopts computer programming, servo motor feeding and positioning, multiple sets of molds can be installed at the same time. And it has extremely powerful processing capabilities.

Compared with ordinary punching machines, it has been greatly improved. It can complete many tasks that cannot be completed by ordinary punching machines, and can even complete part of the work of drilling machines, tapping machines, and bending machines.

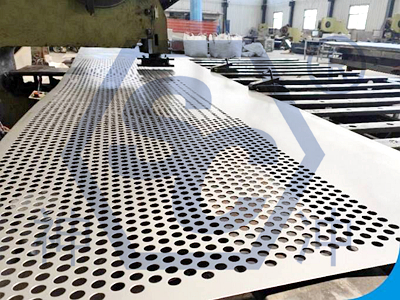

Specifically, the following tasks can be completed: punching, tapping, flanging, small-height bending, rolling, forming of ventilation holes, etc. Through various combinations, flat sheet metal parts of any shape can be processed.

The design principle of the CNC punching machine is to convert the circular motion into a linear motion. The main motor drives the flywheel, and the clutch drives the gear, crankshaft (or eccentric gear), connecting rod, etc. to achieve the linear motion of the slider.

From the main motor, the motion to the connecting rod is a circular motion. There must be a transfer point between circular motion and linear motion between the connecting rod and the slider. There are roughly two types of mechanisms in its design, one is ball type, and the other is pin type (cylindrical type).

Through this mechanism, the circular motion converted to linear motion of the slider. The punch press applies pressure to the material to make it plastically deformed to obtain the required shape and precision.

Therefore, a set of molds (upper mold and lower mold) must be used to place the material in between, and the machine applies pressure to deform it. The reaction force caused by the force applied to the material during processing is absorbed by the punch machine body.

Click here to know: Ironworker Punching And Shearing Machine Using Guide

CNC punching machines are widely used in stamping and forming of electronics, communications, computers, household appliances, furniture, vehicles, (automobiles, motorcycles, bicycles) hardware parts, etc.

- It is directly driven by a high-torque servo motor. Higher precision, stable and reliable, punching frequency up to 1500 times/min.

- The bed adopts three-dimensional software design, and after the finite element analysis and verification experiment, the structure is reasonable and the rigidity is good, which ensures the long-term stability of the machine tool precision.

- After the bed is welded, it undergoes strict low-temperature annealing treatment to completely eliminate the welding stress and avoid deformation of the machine tool due to the release of welding stress during use.

- The integral bed has high assembly precision, low requirements on the foundation, and easy installation.

- It can run continuously for a long time.

- The main shaft adopts servo motor direct drive to improve maintainability, greatly reduce energy consumption, and has the advantages of low noise, high speed and low vibration.

- Automatically select the punching force, the energy consumption is 1/3 of that of the hydraulic punching machine, and it can realize punching processes such as bead rolling, engraving, and silent processing.

- The processing range of the equipment can be customized according to the needs of customers

CNC punching machine is an automatic punching machine equipped with a numerical control system. Compared with ordinary punching machines, the characteristics of CNC punch pressing machines are as follows:

- There are fewer molds than ordinary punching machines, and complex shapes can be completed by nibbling punching and nibbling punching.

- High processing precision, ball screw + servo control to ensure high-precision sheet metal parts.

- The processing speed is fast, one CNC punch can complete the work of ten ordinary punches.

- Small-sized bending and stretching can be molded, and can be processed for shutters, bridge holes, flanging and other forming processes.

- Less power consumption, no auxiliary gas, much less cost than laser cutting machine.

- Adapt to a variety of sheet metal materials, carbon steel, aluminum plate, copper plate, aluminum-zinc plate, hot-dip galvanized plate, epoxy resin plate can be processed.

CNC punching machines can be divided into:

Utilize the rotational inertia of the flywheel to drive the striking head for stamping.

Advantages: cheap and easy to maintain.

Disadvantages: loud noise, limited tonnage.

The hydraulic cylinder motor is used to drive the striking head for impact.

Advantages: low noise, high tonnage.

Disadvantages: high cost, requiring assemblers to maintain. Hydraulic punches can be divided into hydraulic punches and hydraulic punches according to the liquid they use. At present, most hydraulic presses are used, while hydraulic presses are mostly used for large-scale mechanical special machines.