Steel plate is one of the four major varieties of steel (plate, pipe, type, wire). In developed countries, the output of steel plate accounts for more than 50% of the total steel production. With the development of my country's national economy, the production of steel plate is gradually increasing.

A steel plate is a flat steel material with a large aspect ratio and surface area. Steel plates are divided into two specifications: thin plate and thick plate according to their thickness. Thin steel plate is a steel plate with a thickness between 0.2-4mm produced by hot rolling or cold rolling. The width of the thin steel plate is between 500-1400mm. According to different purposes, thin steel plates are rolled from billets of different materials. Commonly used materials include ordinary carbon steel, high-quality carbon steel, alloy structural steel, carbon tool steel, stainless steel, spring steel and silicon steel for electrical purposes. They are mainly used in the automobile industry, aviation industry, enamel industry, electrical industry, machinery industry and other sectors.

Thick steel plate is a general term for steel plates with a thickness of more than 4mm. In actual work, steel plates with a thickness of less than 20mm are often called medium plates, steel plates with a thickness of >20mm to 60mm are called thick plates, and steel plates with a thickness of >60mm need to be processed in a special It is rolled on a special thick plate rolling mill, so it is called extra thick plate. The width of thick steel plate is from 0.6mm-3.0mm. Thick plates are divided into shipbuilding steel plates, bridge steel plates, boiler steel plates, high-pressure vessel steel plates, checkered steel plates, automobile steel plates, armor steel plates and composite steel plates according to their uses.

Today we mainly talk about eight types of ordinary medium and thick steel plates.

Plain carbon steel boiling steel plate, as the name implies, is a steel plate made by hot rolling of ordinary carbon structural steel boiling steel. Boiling steel is a kind of steel with incomplete deoxidation. The molten steel has a high oxygen content. When the molten steel is poured into the ingot mold, a large amount of gas will be generated by the reaction of carbon and oxygen, causing the molten steel to be in a boiling state.

Boiling steel plates are widely used to manufacture various stamping parts, architectural and engineering structures and some less important machine structures and parts.

It meets the requirements of boiling steel in GB700-79 (88) (technical conditions for ordinary carbon structural steel).

The thickness of the hot-rolled thick steel plate is 4.5-200mm.

Common carbon killed steel plate is a steel plate made by hot rolling of ordinary carbon structural steel killed billet. Killed steel is completely deoxidized steel. The molten steel is fully deoxidized with ferromanganese, ferrosilicon and aluminum before casting ingots. The molten steel is relatively calm in the ingot mold and does not produce a boiling state, so it is named killed steel.

Ordinary killed steel plates are mainly used to produce components that withstand impact at low temperatures, welded structures and other structural parts that require higher strength.

It meets the requirements of killed steel in GB700-79(88) (technical conditions for ordinary carbon structural steel). Refer to section steel etc.

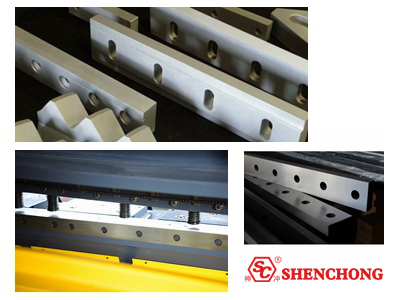

Hot-rolled thick plate thickness 4.5-200mm. Steel Cutting Blade for Plate Shearing Machine Material is 9CrSi, 6CrW2Si, Cr12MoV, H13K etc.

Low alloy structural steel plate is made by hot rolling of low alloy structural steel. Low-alloy steel plates are all killed steel and semi-killed steel plates. Its advantages are higher strength, better performance, saving a lot of steel, reducing structural weight, etc.

Low-alloy structural steel plates are more and more widely used in machinery manufacturing and metal structural parts.

See relevant sections of section steel.

The thickness of the hot-rolled steel plate is 4.5-200mm.

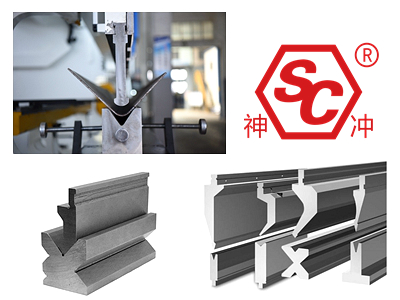

Press Brake Punch and Die material is T7 or 42CrMo, we can design according to your requirement or your work pieces.

It is mainly used in general structures such as buildings, bridges, and vehicles.

Steel plate (strip) thickness from 1.2-13.0mm; width from 700-1550mm; length from 2000-12000mm.

Weather-resistant steel is atmospheric corrosion-resistant steel. Weather-resistant steel for welded structures is to add a small amount of alloying elements, such as steel, chromium, nickel, molybdenum, niobium, titanium, zirconium and vanadium, etc., to form a protective layer on the surface of the metal substrate to improve the weather resistance of the steel. and good welding performance.

Mainly used in bridges, buildings and other structures.

Weather-resistant steel is resistant to atmospheric corrosion. A small amount of alloying elements are added to the steel, such as steel, phosphorus, chromium, nickel, molybdenum, niobium, titanium, zirconium and vanadium, etc., to form a protective layer on the surface of the metal substrate and improve the weather resistance of the steel.

Mainly suitable for buildings, vehicles, towers and other structural parts.

Patterned steel plate is a steel plate with rhombus or lentil-shaped ribs on its surface. Its specifications are expressed by its own thickness (thickness of ribs is not counted).

The checkered plate has anti-slip effect and is often used as floor, factory escalator, work frame pedal, ship deck and automobile floor, etc.

The checkered plate is made of ordinary carbon structural steel B1, B2 and B3, and its chemical composition meets the requirements of GB700-79 (technical conditions for ordinary carbon structural steel).

Bridge steel plate is a steel plate specially used for erecting railway or highway bridges. It is required to have high strength, toughness and withstand the load and impact of rolling stock, as well as good fatigue resistance, certain low temperature toughness and atmospheric corrosion resistance. Steel for tie-welded bridges should also have good weldability and low notch sensitivity.

It is mainly used for structural parts of railway bridges and highway bridges with a span of 46-160mm.

Thickness from 6-50mm width from 1.0-2.4mm length from 2.0-16m.