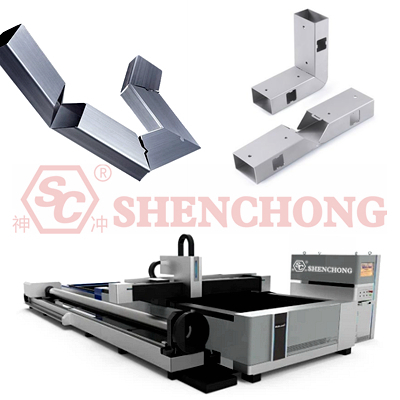

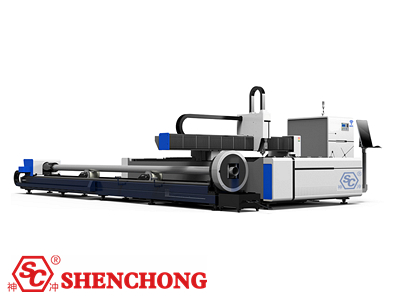

What are the cutting advantages of tube & pipe laser cutting machines? With the development of laser cutting technology, the application range of laser cutting machines is becoming more and more extensive.

In addition to cutting steel plates, cutting pipes is also very practical. After the laser cutting machine cuts the pipes, only a narrow slit will be left. It is almost as wide as the laser beam, and has the advantages of being able to cut in multiple different directions, cutting beveled end faces at the ends of round pipes, cutting steel pipes without causing deformation or collapse of the outer surface of the pipe, and with high cutting accuracy.

Laser cutting machine is a machine used to cut workpieces. It is generally used to cut various metal plates, and some are also used to cut some non-metallic materials. Pipes are used in the manufacturing industry or

It is an indispensable workpiece in the industry, so can pipes be cut with laser cutting machines? It is understood that traditional cutting technology is not suitable for cutting irregular surfaces of pipes, and the cutting effect is not very ideal, which may cause pipe damage. Deformed and damaged, even if it is cut, there may be problems with burrs and irregularities on the edges. However, the laser cutting technology used by laser cutting machines is very practical for cutting irregular surfaces of pipes.

When the laser cutting machine cuts the pipe, the laser beam penetrates the pipe and moves along the set cutting position while melting the material. After cutting, only a narrow slit will be left, which is almost as wide as the laser beam.

Nowadays, laser cutting machines are generally used for pipe cutting. Compared with other pipe cutting machines, pipe laser cutting machines mainly have the following advantages:

- It can cut multiple intersecting cylinders with different directions and diameters on the main pipe. The line hole satisfies the conditions for the vertical intersection of the branch pipe axis and the main pipe axis to be eccentric or non-eccentric.

- It can cut the oblique end face at the end of the round pipe.

- Can cut the end of the branch pipe intersection line that intersects the ring main pipe.

- Can cut variable angle bevel surfaces.

- Can cut square holes and waist shapes on round tubes.

- Ability to cut steel pipes.

- Can cut various graphics on the square tube surface.

- The non-contact processing method is used. During the entire processing process, there will be no pressure on the pipe wall, so it will not cause deformation or collapse of the outer surface of the pipe.

- The cutting accuracy is high and can be flexibly adjusted according to the slight expansion and contraction deformation that occurs during the cutting process.

The construction industry is one of the main application industries for pipe laser cutting machines. With the development of society, the modern construction industry has increasingly higher requirements for the quality and precision of building components, and traditional manual cutting methods can no longer meet the demand. Due to its high precision and high efficiency, tube and pipe laser cutting machines have become one of the indispensable equipment in the construction industry.

In the construction industry, pipe laser cutting machines can be used to produce steel structural systems of various shapes and sizes, such as bridges, high-rise buildings, steel structure houses, etc. Through the cutting of the pipe laser cutting machine, the accuracy and precision of the steel structure can be guaranteed, thereby enhancing the stability and safety of the building.

The automobile manufacturing industry is also one of the main application industries for tube laser cutting machines. In the automobile manufacturing process, various types of metal pipes are used in large quantities, such as frames, chassis, exhaust pipes, etc. The traditional manual cutting method is inefficient and error-prone, but using a pipe laser cutting machine can improve production efficiency and product manufacturing accuracy.

The pipe laser cutting machine can complete the cutting and processing of steel pipes in a shorter time, thereby improving the efficiency of automobile manufacturing. In addition, due to the high processing accuracy of the pipe laser cutting machine, the accuracy and smoothness of the steel pipe after cutting can be guaranteed, as well as the quality of the product.

In the aerospace industry, tube laser cutting machines are also widely used. In the aerospace manufacturing process, a large number of high-strength and high-precision pipes are required, such as aerospace engines, aircraft structures, satellites, etc.

The pipe laser cutting machine can cut and weld quickly and accurately, and can also meet the requirements of various complex shapes, thereby improving the manufacturing accuracy and quality of the product. In addition, in the field of aerospace manufacturing, pipe laser cutting machines can also be used to process complex-shaped pipes and difficult materials such as titanium alloys.

In the rail transit industry, tube & pipe laser cutting machines are also widely used. For example, transportation facilities such as subways, high-speed rails, and urban light rails require a large amount of steel pipes of various shapes to be constructed.

By using a pipe laser cutting machine for cutting, the production process can be greatly optimized and production efficiency enhanced. In addition, compared with traditional cutting methods, pipe laser cutting machines have faster cutting speeds, smaller errors, and more stable cut quality, thereby improving the processing technology level and manufacturing quality of steel pipes.

The pressure vessel manufacturing industry is one of the important application industries for tube pipe laser cutting machines. During the manufacturing process of pressure vessels, steel pipes need to be cut and welded, which requires equipment with high precision and efficiency.

By using a pipe laser cutting machine for cutting and welding, production efficiency and product manufacturing accuracy can be improved. In addition, the pipe laser cutting machine can also perform complex processes such as integral cutting, pin assembly and welding, thereby further improving the manufacturing accuracy and quality of the product.

In the steel and metallurgical industry, pipe and tube laser cutting machines are also widely used. In the steel production process, steel products of various sizes need to be cut and processed, such as rails, steel plates, steel wires, etc.

Using a pipe laser cutting machine for cutting and processing can improve production efficiency and product manufacturing accuracy. Pipe tube laser cutting machines can also meet the requirements of various complex shapes, thereby improving the quality and manufacturing level of steel products.

To sum up, the tube & pipe laser cutting machine is a high-precision and high-efficiency metal processing equipment widely used in various industries. It can improve production efficiency and product manufacturing accuracy, so it is widely used in many industries such as construction, automobiles, aerospace, rail transit, pressure vessel manufacturing, and steel metallurgy.