Sheet metal processing, as the name suggests, is the process of using metal sheets to produce the necessary items according to needs. Commonly used materials in daily life include computer cabinets, TV backboards, car casings, air conditioning casings, terminal integrated casings, charging station boxes, etc. What are the sheet metal processing techniques?

Sheet metal processing technologies mainly includes plate cutting, bending, laser cutting, plasma cutting, flame cutting, drilling, rolling, bending, etc. All sheet metal processing techniques are based on the need for engineers to design product drawings and annotate product specifications before operation. So what are the common sheet metal processing technologies?

- Review the drawings and select relevant materials according to the requirements of the drawings.

- Check the dimensions and draw lines before cutting.

- Feed the work piece into the cutting machine through the workbench, first remove the burrs, and then use a tape measure to measure and draw the line.

- Align the drawing lines through the alignment light of the cutting machine.

- Use a foot pedal to control blade movement.

- The cutting edge of the shearing machine is low on the left and high on the right.

- The cutting machine can not only cut plates but also rubber.

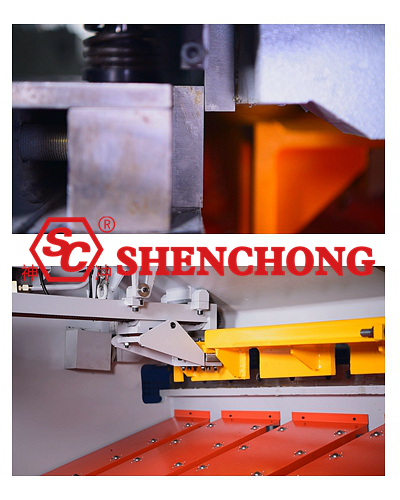

- During the cutting process, the cutting edge of the shearing machine first clamps the workpiece with a clamping device and then cuts it.

- The shell of the pedal switch is severely damaged, posing a safety hazard. It is recommended to regularly maintain the pedal.

- After the cutting machine completes the cutting, the workpiece directly falls onto the floor from behind the cutting machine. It not only causes loud noise but also causes certain damage to the workpiece. It is recommended to create an inclined double track or ramp behind the cutting machine to slide the processed workpiece along the track, reducing noise and damage.

- Review the drawing to see if the unfolded dimensions of the bent parts are correct and if the bending dimensions are appropriate.

- Select a suitable mold and lock it according to the thickness and angle of the bent sheet material.

- To facilitate the control of bending length, a backup plate needs to be installed.

- Input data through the control cabinet according to the dimensions given in the drawing

- Install the bending sheet, measure the distance of the sheet on the Press brake, and check whether the entered data is correct.

- Control the movement of the cutting tool through a foot pedal.

- Measure whether the size of the first workpiece meets the requirements. If it meets the requirements, directly process the remaining OEM sheet materials. If it does not meet the requirements, adjust the data of the control cabinet.

- Bending should consider bending rebound and bending stretching, and set the data by calculating the bending coefficient.

- When designing, it is necessary to consider the minimum bending angle and minimum bending length for different plate thicknesses. Workpieces smaller than the minimum bending angle and minimum bending length cannot be processed.

- Do not weld workpieces that can be bent.

- Half circles that cannot be folded can be folded into two quarter circles to be welded together.

- The bending die is a Rectangular cuboid, and there are bending dies of different sizes on the four long rectangular faces. When another size of mold needs to be used, unlock, flip, and lock it.

For some bending parts with low precision requirements, such as the circle obtained by multiple bends, workers generally do not draw lines and control the bending distance based on experience.

- Design to bend the sheet into a U-shaped shape, with the bottom length being greater than the length on both sides.

- Use a crane to place the plates that need to be processed on the working surface.

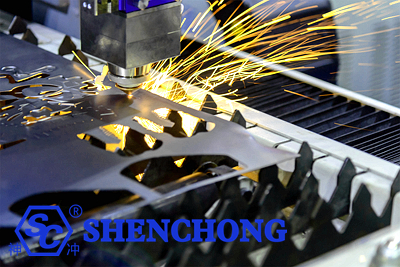

- Fix the edge and point, operate the CNC machine to control the laser point to walk one circle along the sheet metal boundary to determine the sheet metal processing boundary.

- Import the data information of the drawing into the CNC machine tool.

- Film blowing, laser cutting machine pre processing.

- Laser cutting machine processes the sheet metal.

- When the board is placed outdoors, there will be rust and oxide film, while laser cutting has a better processing effect on a flat surface. Therefore, it is necessary to pre process and remove the rust and oxide film on the board surface.

- The pads on the processing platform may be damaged due to laser cutting during the processing, so it is necessary to frequently replace the metal pads.

After the processing is completed and the formed parts are knocked down, the remaining metal frame is relatively large and inconvenient for transportation, so gas cutting will be used to cut the remaining metal frame. Due to the fact that laser cutting creates a gap between the formed part and the frame, it will not damage the formed part during the gas cutting process.

- Laser cutting has high accuracy, is faster than traditional mechanical cutting, has no shape restrictions, saves materials, has smooth cuts, good repeatability, and good material processing uniformity. However, for small holes, manual hole rotation is generally used, and laser cutting is mainly used for processing thin plates and plates with good surface flatness.

- Laser cutting holes with a diameter greater than the plate thickness.

- Use a crane to place the board properly.

- Import the machining program and adjust the machining parameters.

- Set the starting point for processing, starting from the starting point.

- Plasma cutting speed is higher than laser cutting, but the quality is not as good as laser cutting.

- Plasma cutting has little thermal deformation and almost no thermal impact.

- Plasma cutting for direct processing requires water to prevent dust.

- Adjust the plate so that the processed steel plate remains parallel to the track.

- Select an appropriate cutting nozzle based on the thickness and material of the plate, so that the cutting nozzle is perpendicular to the steel plate.

- According to different plate thicknesses and materials, reset the cutting speed and preheating time in the machine, and set the reasonable pressure for preheating oxygen and cutting oxygen.

- Start the ignition and cut according to the program. After the cutting is completed, clean the excess frame and place the cut workpiece in the designated position.

- The allowable maximum plate thickness of flame cutting is greater than that of laser cutting and plasma cutting, mainly used for cutting thick plates, with a thickness range of 25-150mm and good accuracy.

- The fuel used for flame cutting is oxygen and acetylene, and the worker will mix it in a certain proportion according to the actual situation.

- Cutting a circle means cutting from the inside out, while cutting a square means cutting directly along the contour.

- Place the workpiece on the workbench and tighten it.

- Use the operation cabinet to import the program, adjust the starting point of the work, and select the correct processing area on the control cabinet

- Press the button to automatically rotate the hole.

- Before processing, raise the front roller and align the sheet material with the upper roller.

- Control the movement of the rollers through the control cabinet.

- If the diameter of the symmetrical rolling plate is too large, it is necessary to weld a crossbar in the direction of the full circle diameter to prevent deformation.

- The mold can be replaced according to the desired shape. The maximum pressure of a four column hydraulic press is 5000 tons. The three working hours directly place the workpiece on the mold for processing. When the requirements are high, positioning is necessary.

- Adjust the dial on the clamping device according to the drawing requirements to determine the angle of the bent pipe.

- Place the workpiece on the workbench, measure it in full size, and then clamp the workpiece.

- When starting to bend, guess and place the workpiece after the bend.

- Measure the distance between each hole on the workpiece according to the drawing to determine the blank position, and use a punch sample to punch and mark the spot.

- Clamp the workpiece, select the drill bit according to the aperture and set the number of revolutions.

- Control the rocker drill to align with the marked points for drilling.