With the development of the laser industry, laser cutting machines have gradually replaced traditional metal cutting process equipment. So how to classify laser cutting machines? What are the types of laser cutting machines?

Laser cutting has high precision, fast cutting speed, is not limited to cutting patterns, automatic layout saves materials, smooth incisions, and low production costs.

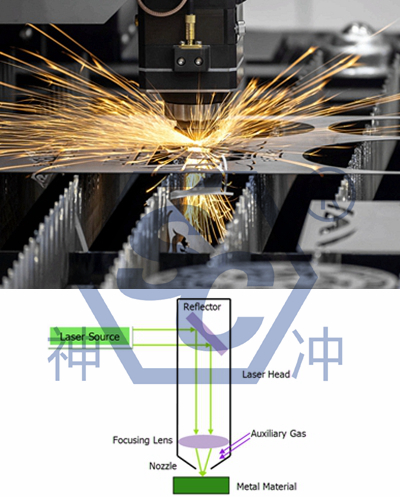

A laser cutting machine focuses the laser emitted from the laser into a high-power density laser beam through an optical path system. The laser beam irradiates the surface of the work piece, causing it to reach its melting or boiling point, while the high-pressure gas coaxial with the beam blows away the melted or vaporized metal. As the beam of light moves relative to the work piece, it ultimately forms a cutting seam in the material, thereby achieving the purpose of cutting.

Click here to know more about laser cutting working principle:

Working Principle And Composition Of CNC Laser Cutting Machines

So how to classify laser cutting? What are the types of laser cutting machines?

It can be divided into low-power laser cutting machines, medium power laser cutting machines, and high-power laser cutting machines.

The laser output power varies, and the application fields also vary. In the industrial field, high-power fiber laser cutting machines are mainly used, but in the field of laser engraving, medium and low-power laser engraving and cutting machines are mainly used.

Metal laser cutting machines are used to cut metal materials, while non-metal laser cutting machines are used to cut non-metal materials.

It is generally divided into standard format laser cutting machines and non-standard ultra large format laser cutting machines. The X-axis cutting length of the ultra large format laser cutting machine is mainly above 8000mm.

Cutting plates can be divided into flat cutting and 3D cutting. Flat plates are generally cut using flat laser cutting machines, while 3D solid plates can be cut using robot laser cutting machines, 3D five axis laser cutting machines, etc.

According to the type of laser used in cutting machines, they can be divided into fiber laser cutting machines, CO2 gas laser cutting machines, and YAG laser cutting machines.

At present, YAG laser cutting machines have been phased out. Fiber laser cutting machines are currently the mainstream in the domestic market. Good cutting quality, high precision, and fast efficiency are increasingly sought after by more and more metal processing enterprises.

There are currently three popular types of laser cutting machines in the market: fiber laser cutting machines, carbon dioxide laser cutting machines, and YAG laser cutting machines.

Their respective advantages, disadvantages, and market positioning are:

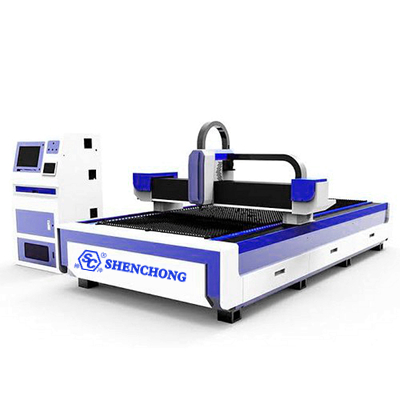

High photoelectric conversion rate, low power consumption, capable of cutting stainless steel plates and carbon steel plates up to 12mm. It is the laser cutting machine with a faster cutting speed for thin plates among these three types of machines. It has small slits and good spot quality, which can be used for fine machining.

Currently, most of the core key technologies of fiber lasers are controlled by one or two manufacturers in Europe, America, and other countries, so most machines are expensive.

Most machines are priced at over 1.5 million yuan, and low-power ones are also around 500000 yuan. When cutting, the fiber laser is very thin and consumes a huge amount of gas (especially in nitrogen cutting). In addition, it is difficult or even impossible for fiber laser cutting machines to cut high reflective materials such as aluminum and copper plates, and the speed is very slow when cutting thick plates.

Cutting below 12mm, especially high-precision machining of thin plates, mainly targeting manufacturers who have extremely high requirements for machining accuracy and efficiency. It is estimated that with the emergence of 5000W and above lasers, fiber laser cutting machines will eventually replace most cutting machines in the CO2 high-power laser market.

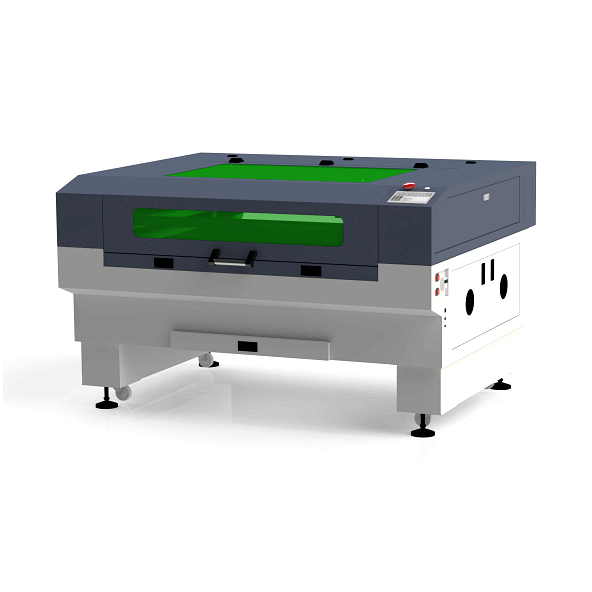

High power, generally between 2000-4000W, capable of cutting conventional materials such as stainless steel and carbon steel up to 25mm, aluminum plates up to 4mm, acrylic plates, wooden plates, PVC plates up to 60mm, and cutting thin plates very quickly.

In addition, due to the continuous output of CO2 laser, it has the smoothest and better cutting section effect among the three laser cutting machines during the cutting process.

Due to the fact that most of the core and key technologies of CO2 lasers are controlled by European and American manufacturers, most machines are expensive, with a cost of over 2 million yuan. Only domestic manufacturers with strong capabilities have invested a large amount of funds in researching and developing core technologies.

Cutting and processing of 6-35mm medium and thick plates, mainly targeting large and medium-sized enterprises and some purely external laser cutting and processing enterprises

In recent years, the market has been greatly impacted by solid-state laser cutting machines and fiber laser cutting machines. The market is in a significant contraction state. However, some financially strong companies are still adept at navigating the market, leaving a private space for China's core technology.

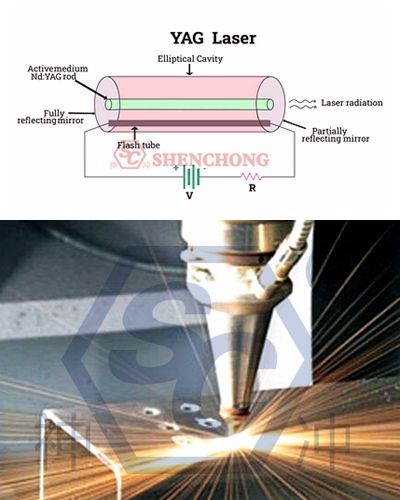

It can cut aluminum plates, copper plates, and most non-ferrous metal materials that cannot be cut by other laser cutting machines. The purchase price of the machine is cheap, the usage cost is low, and the maintenance is simple.

Most of the key technologies have been mastered by domestic enterprises. Low accessory prices and maintenance costs, simple machine operation and maintenance, and low requirements for worker quality.

It can only cut materials below 8mm, and the cutting efficiency is relatively low.

Cutting below 8mm, mainly aimed at self use small and medium-sized enterprises and most users in industries such as sheet metal manufacturing, home appliance manufacturing, kitchenware manufacturing, decoration, advertising, etc. with low processing requirements, gradually replacing wire cutting and CNC punching machines. Traditional processing equipment such as water cutting and low-power plasma.