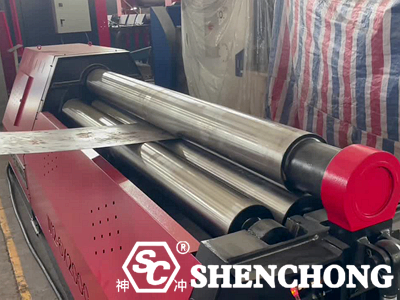

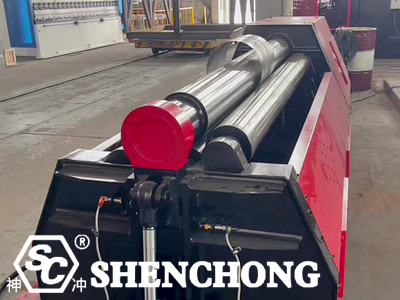

SHENCHONG Egypt Four-Roller Plate Rolling Machine W12-6X2000mm is a high-precision, high-efficiency sheet metal forming machine that can roll metal sheets with a maximum thickness of 6mm and a maximum width of 2000mm into cylinders, cones, and multi-section curved work pieces in one operation.

This machine features CNC-controlled upper roll adjustment and hydraulically driven lower and side rolls. It automatically performs pre-bending, rolling, and shaping during the rolling process. It is easy to operate, safe, and reliable, and is widely used in industries such as sheet metal, boilers, pressure vessels, ventilation ducts, automobiles, shipbuilding, petrochemicals, and metal structure manufacturing.

- Upper Roller: The main drive roller, driven by a motor and a reducer, moves up and down to adjust the rolling pressure.

- Lower Roller: Fixed in position, used to clamp and convey the plate.

- Side Rollers: Driven by hydraulic cylinders, pre-bend and shape the plate.

- Main Frame: Constructed of high-quality welded steel plates, tempered to eliminate stress, ensuring rigidity and long service life.

- Hydraulic System: Provides the power for raising and lowering the rollers and clamping them, and features overflow protection and automatic pressure replenishment.

- Electrical Control System: Centralized push-button operation, equipped with an operation panel, emergency stop button, and safety interlock.

- Optional Auxiliary Devices: Roller support frame, discharge device, tapered rolling device, etc.

Before rolling, the edges of the plate are pre-bent to reduce residual straight edges, thereby improving the quality of subsequent welding or cylindrical splicing. The W12 series supports pre-bending and rolling operations with a single loading process.

The upper roll is the primary driver, while the lower and side rolls are raised and lowered to control the rolling process. This structure enables the rolling of curved, cylindrical, and even conical shapes under certain conditions.

Motions such as lifting and side roll adjustment are often hydraulically driven; some models are equipped with CNC/PLC systems that can store programs for automatic control.

To ensure rolling accuracy, the machine typically features automatic leveling and axial alignment to ensure roller parallelism and plate forming quality.

Most models are equipped with safety interlocks, a screen display, and other protective features.

- Pre-bending and rolling are completed in one loading operation

No sheet turning is required, saving operation time and improving production efficiency.

- High-precision Control

The upper roller position is hydraulically synchronized to ensure high roundness and excellent concentricity during rolling.

- Easy, safe, and reliable operation

Centralized control console operation, equipped with emergency stop and overload protection devices, ensures safe operation.

- Sturdy structure and long service life

The frame is fully welded and annealed, ensuring strong resistance to deformation.

- Sheet metal fabrication workshops

- Stainless steel product manufacturing

- Pressure vessel manufacturing

- Ventilation and duct processing

- Construction and decoration industries

- Shipbuilding, aviation, and machinery manufacturing

Wuxi Shenchong has entered the Egyptian market for many years. We have local distributors and professional service team. Every year, we export a large number of press brakes, shearing machines, and plate rolling machines to Egypt and various countries in Africa and the Middle East. Inquiries are welcome!