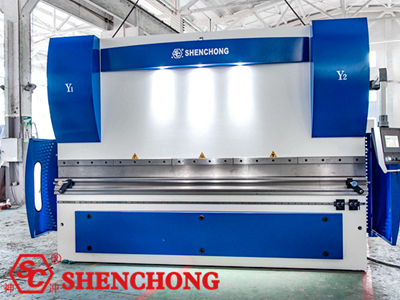

SHENCHONG 3mm stainless steel bending machine for sale is a metal forming equipment specially used for precision bending of stainless steel plates with a thickness of 3 mm. Due to the high strength and resilience of stainless steel materials, the rigidity, pressure and control accuracy of the bending equipment are required to be high. It is widely used in kitchen equipment, elevator parts, mechanical housings, decorative components, sheet metal parts and other fields. The following is a detailed introduction to this type of press brake bending machine.

- Maximum plate thickness (stainless steel): 3mm (adjust pressure according to plate tensile strength and bending width)

- Bending length: 4000mm

- Nominal pressure: 250 tons

- Slider stroke: usually 100-300mm (depending on bending depth)

- Control system: ESA S640

- Main machine frame: welded steel structure with high rigidity and stability.

- Upper and lower molds: mainly V-shaped molds, special molds need to be selected according to stainless steel material and bending angle.

- Hydraulic system: provides uniform and strong pressure for extruding metal plates between upper and lower molds.

- CNC system: used to set bending angle, back gauge position, multi-pass bending sequence, etc.

- Back gauge device: accurately locates plate position and supports multi-axis servo drive.

- Operation panel and foot switch: control the whole machine operation, supports manual, single and continuous modes.

- Kitchen equipment: right-angle or rounded bends for stainless steel countertops and cabinet door panels

- Electrical box: door panels and frame processing for control boxes and distribution boxes

- Medical device housing: bend stainless steel housings to meet corrosion resistance and strength requirements

- Architectural decoration: molding of decorative components such as stainless steel guardrails, edging strips, and lines

- Complex, precise, and batch bending of stainless steel plates can be achieved.

- The CNC system supports automatic programming for multiple bends.

- High-precision backgauge ensures consistency.

- Degreasing and scratch prevention are required before bending.

- Bending molds need to be regularly inspected to avoid angle errors.

- Stainless steel is prone to rebound, and the bending angle needs to be appropriately increased for compensation.

If you need to know more about the model selection, technical parameters, price information, or obtain product manuals of Shenchong stainless steel bending machine for sale, please contact us.