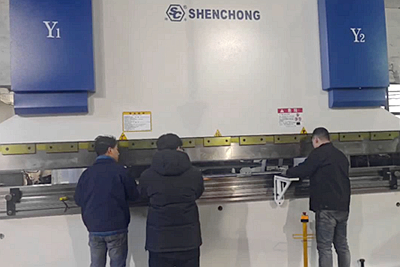

SHENCHONG main motor servo CNC press brake 300t 4500mm is a very popular model in the sheet metal processing industry. It belongs to a new generation of energy-saving, efficient and more precise bending equipment. The main motor servo means that the slider drive system of the bending machine is directly controlled by the servo motor, replacing the traditional hydraulic drive method.

SC WSK main motor servo CNC press brake 300 tons 4500mm EL15T 4+1 axis is suitable for bending medium and thick plates. The maximum bending pressure is 300 tons. The maximum bending length is 4500 mm.

The single servo CNC bending machine is driven by a servo motor system. Compared with the traditional hydraulic bending machine, it has the advantages of energy saving and high precision, but it may be slightly inferior to the dual servo system in terms of synchronization.

Item | Parameters |

Equipment type | Single servo CNC bending machine |

Nominal pressure | 300 tons |

Bending length | 4500 mm |

Control system | EL15T CNC controller (domestic, economical or mid-to-high-end model) |

Number of control axes | 4+1 axis (usually Y1, Y2, X, R + V axis or Z1/Z2) |

Drive mode | Single servo (servo control, may only drive the main slide or back gauge) |

Workbench structure | Welded steel frame structure, hydraulic or electric compensation |

Different from traditional hydraulic press brake machine:

- Traditional hydraulic bending machine: hydraulic oil is used to push the slider up and down.

- Main servo press brake machine: a servo motor + ball screw + synchronous belt is used to directly drive the slider up and down.

Motion control:

- The up and down movement of the slider is precisely controlled by the servo motor through the encoder.

- The back gauge (X/R/Z axis) is also driven by the servo motor.

- The CNC system performs closed-loop control on all axes to achieve high-precision bending.

EL15T controller is a mid-range or high-end product in China's CNC system.

Common functions:

- Touch screen interface, Chinese menu

- Support graphic programming/process library

- Automatic arrangement of multi-step bending programs

- Automatic calculation of bending angle and back gauge position

- Rich communication interface, can connect to servo system, PLC, remote diagnosis

- Suitable for processing medium and thick plates, especially long workpieces and products with high precision requirements.

- Energy saving and environmental protection: single servo system has lower noise and energy consumption than traditional hydraulic system.

- High repeatability: servo motor has precise control and good bending consistency.

- Commonly used in manufacturing industries such as power cabinets, sheet metal parts, billboards, doors and windows, and structural parts.

- If you mainly process repeated batches and less complex sheet metal parts, this main motor servo CNC press brake 4+1 axis is enough.

- If you are processing complex multi-fold workpieces and have high requirements for speed and synchronization, it is recommended to consider servo hybrid CNC press brake WDK series 6+1 axis or above configuration.

- EL15T is a cost-effective controller, stable and reliable. But if you pursue higher-end functions, you can consider other brands such as ESA or Delem.