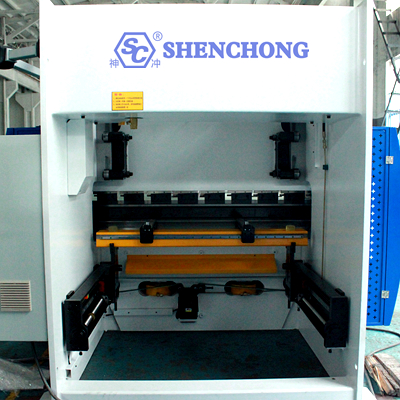

CNC plate bending machine is an equipment used to bend metal sheets into various angles. It is widely used in sheet metal processing, machinery manufacturing, automobile, aviation, home appliances and other industries. The following is a detailed introduction to the 2mm metal plate CNC bending machine for sale.

SC 2mm metal sheet CNC plate bending machine is a CNC bending equipment designed for metal sheets with a thickness of 2 mm (such as carbon steel, stainless steel, aluminum alloy, etc.). It controls the movement of the bending slider through the CNC system to achieve high-precision and high-efficiency sheet bending processing.

Integral welded structure, tempering or vibration aging treatment is used to ensure that the machine body does not deform during long-term use.

The upper die is installed on the slider to complete the downward pressing action, which is the core actuator of the bending.

Used to support the lower die and withstand the bending force.

Control the Y axis (slider moves up and down), X axis (back gauge moves forward and backward), etc.

Support graphic programming and angle programming.

Provide the pressure required for slider movement, using imported or domestic high-quality hydraulic pumps and valve groups.

Used to position the workpiece to ensure accurate size.

The upper and lower molds can be replaced according to different bending angles and shapes.

The material is mostly high-strength alloy steel.

Components | Description |

Machine body | High-strength steel plate welding structure, tempering stress relief treatment, strong resistance to compression deformation |

Slider system | The upper die is installed on the slider to perform the bending action |

Electro-hydraulic servo system | Control the left and right cylinders precisely and synchronously, the core technology part |

CNC system | Control the Y1, Y2, X, R and other axes to execute programmed bending commands |

Grating scale | Real-time detection of slider position, feedback closed-loop control |

Back gauge system | Control the sheet position, multi-axis (X, R, Z axis) |

Hydraulic system | Servo proportional hydraulic control, fast response, high precision |

Mold system | Diversified selection of upper and lower molds to meet different angles/workpiece shapes |

Item | Parameter range (example) |

Bending plate thickness | ≤2mm (carbon steel) |

Bending length | 1250mm / 2500mm / 3200mm / 4000mm |

Nominal pressure (tonnage) | 40T, 63T, 80T, 100T |

Number of control axes | 3 axes (Y1/Y2/X) ~ 6 axes (including R/Z1/Z2) |

Repeat positioning accuracy | ±0.01 mm |

Slider stroke | 100–250 mm |

Maximum opening height | 400–600 mm |

Workbench compensation | Optional automatic deflection compensation system |

Power requirements | 380V / 50Hz (customizable) |

- High precision: CNC control ensures angle consistency and dimensional accuracy.

- High efficiency: fast positioning and batch production.

- Easy operation: graphical interface, short worker training time.

- High diversity: can bend a variety of angles and shapes, support complex bending.

- High degree of automation: can integrate automatic loading and unloading, angle compensation, bending auxiliary arm, etc.

- Carbon steel, stainless steel, aluminum alloy, copper plate, galvanized plate, etc.

- Precision sheet metal processing

- Electrical cabinets

- Medical device housings

- Elevators, automatic doors

- HVAC

- Lighting, cabinets, kitchenware

- Aviation parts, automobile parts

When choosing a CNC bending machine, consider:

- Maximum processing length (such as 2.5 meters, 3.2 meters).

- Sheet material and thickness (such as 2mm stainless steel vs 2mm aluminum plate, different tonnage requirements).

- Whether to change molds frequently (quick change molds can be selected).

- Whether an angle compensation system is required (to improve bending consistency).

- Whether multi-axis control is required (such as R-axis lifting and Z-axis lateral movement).

- Budget and brand requirements.

- Do you plan to connect to the automated loading and unloading system/manipulator/robot bending center?

If you have a specific usage scenario (such as what products you plan to process, how much production capacity you require, whether you need fully automatic bending unit, etc.), we can further help you customize the selection suggestions and configuration solutions.