Sheet metal processing is a labor-intensive industry. With the continuous development of science and technology and the increasing competition in the industry, the application of automated processing technology in the field of sheet metal processing is also rapidly popularizing. Automated processing reduces the labor intensity of workers, making sheet metal processing safer and more efficient, with higher precision and more stability.

As an important part of sheet metal processing automation, although bending automation has obvious advantages in efficiency, quality, labor costs, etc., there are still many technical and application difficulties in its implementation process. The following is an analysis of several core difficulties in sheet metal bending automation.

During the bending process, the initial positioning of the sheet metal has a great impact on the final bending accuracy. The automation system needs to solve:

Precise alignment of sheet metal loading.

Displacement error compensation during the bending process.

Stability and anti-interference ability when using visual recognition or sensor positioning.

Sheet metal products are diverse in variety, small in batches and change quickly, while automation equipment is usually optimized for standard parts, and it is difficult to adapt to the following situations:

Quick switching of multiple varieties and small batches.

Processing of special-shaped parts and multiple bends.

Workpiece size, bending angle and sequence vary greatly.

Although the automated bending equipment has CNC functions, it:

The bending program requires manual input or simulation, and the learning curve is steep.

Material elasticity, rebound control, mold selection, etc. still rely on experience.

Lack of intelligent parameter automatic generation system.

Multiple bending requires multiple flipping of the workpiece, and different structural parts exist:

Automatic clamps are difficult to adapt to multi-shaped sheets.

Flipping and handling actions require precise coordination to avoid interference and accidental collision.

The control system and mechanism design requirements are extremely high.

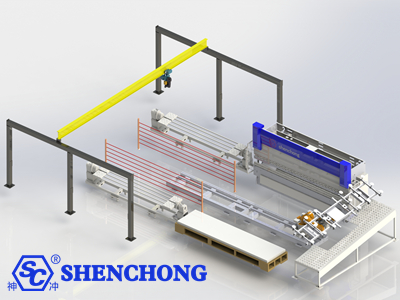

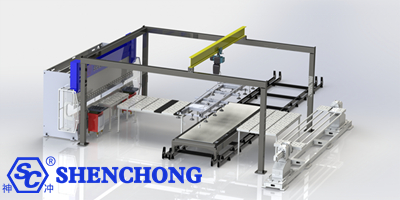

Automated bending units generally include:

Robot arm system

Feeding, unloading, positioning, and flipping units

Intelligent control system

The whole system has high investment and is not friendly to small and medium-sized enterprises.

For non-standard and variable products, sheet metal bending automation is difficult to improve efficiency.

If the product is updated quickly and the bending process changes frequently, it is difficult to improve the utilization rate of the equipment.

The payback period is difficult to control.

Bending is usually closely related to processes such as laser cutting, welding, and stamping.

The automation system needs to be connected to MES, ERP and other systems to ensure seamless process connection.

The requirements for workpiece information transmission, task scheduling, and traceability functions are complex.

Bending automation involves multiple moving parts and there are safety risks.

The detection, feedback, and fault-tolerant processing systems for abnormal situations are still imperfect.

Intelligent protection, laser scanning, limit devices, etc. need to be fully integrated.

Item | Specific difficulties |

Flexibility issues | Poor adaptability to non-standard workpieces, slow changeover |

Precision issues | Difficult to control the accuracy of sheet metal positioning, clamping, and flipping |

Process issues | Difficult to control springback, relying on manual experience |

Cost issues | High equipment investment, long payback period |

Coordination issues | Difficult to link with cutting, loading and unloading processes |

Safety issues | High risk of multi-equipment collaboration |

Although there are many difficulties in bending automation, there are corresponding solutions and optimization methods for each pain point. The following are common difficulties and strategies for dealing with them.

Difficulty:

Slow switching of multiple varieties and small batches.

Special-shaped sheet materials cannot be universally grasped.

Strategy:

Use flexible fixtures and adjustable grippers: Adapt to different sizes and shapes.

Introduce modular mold library: Quickly switch molds.

Deploy MES system to manage process parameters: Automatically match programs, molds and tasks.

Difficulty:

The sheet needs to be repositioned multiple times before and after bending.

Robot grasping is prone to offset and interference.

Strategy:

Integrate high-precision visual positioning system: Automatically identify the edge and hole position of the workpiece.

Design linkage multi-axis robotic arm: Synchronous handling, flipping and positioning.

Use electric permanent magnetic chuck or vacuum gripper: Improve clamping adaptability and stability.

Difficulty:

Bending program and sequence need to be manually input.

Material rebound requires manual judgment and correction.

Strategies:

Introduce 3D simulation bending software (such as Delem, CNC Pro): automatically generate bending sequence and collision detection.

Establish material database and process parameter library: automatic springback compensation and bending angle correction.

Support automatic programming of drawing import (such as DXF): realize "one-click program generation".

Difficulty:

Automation equipment is expensive.

The return cycle is greatly affected by product types.

Strategies:

Prioritize the automation of "highly repeatable" product bending: improve utilization rate.

Adopt modular construction ideas: first install robots + bending machines, and then add vision and flip systems later.

Select economical collaborative robots instead of large six-axis: reduce initial investment.

Difficulty:

Lack of information sharing between cutting, welding and bending.

MES/ERP system cannot link equipment.

Strategy:

Deploy intelligent manufacturing central control platform (SCADA/MES): open up process data flow.

Standardize equipment interface protocol (OPC UA, etc.): realize equipment interconnection and interoperability.

Use QR code/barcode to track workpiece status and process nodes: realize full process visualization.

Difficulty:

Multi-axis collaboration space is complex and easy to collide.

Faults cannot be quickly troubleshooted.

Strategy:

Install laser scanning and force control sensors: realize anti-collision and automatic emergency stop.

Use collaborative robots (with force control sensing): human-machine collaboration is safer.

Deploy remote operation and maintenance and fault diagnosis system: fast positioning and recovery.

Difficulty | Solution strategy |

Poor flexibility | Flexible fixture + mold library + MES scheduling |

Difficult positioning | Vision system + high-precision manipulator |

Difficult programming | Automatic programming + 3D simulation + process library |

Large investment | Phase construction + partial automation |

Difficult coordination | Unified platform + standard interface + barcode traceability |

Poor safety | Sensor + collaborative robot + remote operation and maintenance |