What are the common stainless steel surface treatment processes? What are the stainless steel forming processes? Stainless steel has unique strength, high wear resistance, superior anti-corrosion properties and is not easy to rust. Therefore, it is widely used in industries such as food machinery, electromechanical industry, household appliance industry and home decoration and finishing industry.

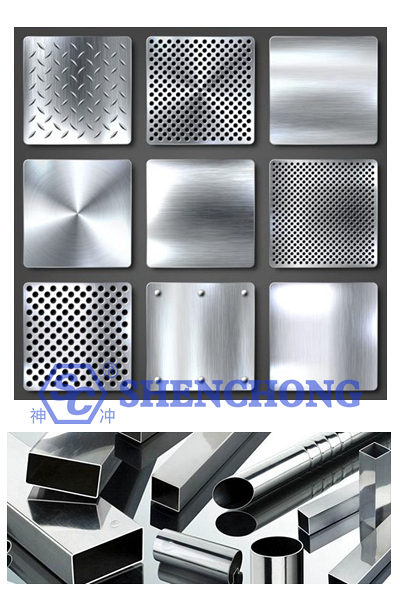

Stainless steel plates have excellent surface treatment and processing properties and can be subjected to various surface processing treatments. The surface of the processed plate can be like a mirror, colorful, or with various patterns.

Different stainless steel surface treatment processes can make the same material highlight different visual effects and feel characteristics. Do you know that there are these 9 surface treatment processes for stainless steel surfaces?

Electroplating refers to PVD vacuum plasma plating, which can be plated with sapphire blue, black, brown, seven colors, zirconium gold, bronze, bronze, rose, champagne gold, light green, etc.

Refers to the process of using physical processes to achieve material transfer and transfer atoms or molecules from the source to the surface of the substrate.

Its function is to spray particles with special properties (high strength, wear resistance, heat dissipation, corrosion resistance, etc.) on a lower-performance substrate, so that the substrate has better properties.

Vacuum evaporation, sputtering, ion plating (hollow cathode ion plating, hot cathode ion plating, arc ion plating, active reactive ion plating, radio frequency ion plating, DC discharge ion plating).

Put the stainless steel plate into the chemical pool to undergo a chemical reaction, and finally obtain a blackened plate surface. The color of water-plated black titanium is darker than that of vacuum. Color difference is 90% controllable. The reasons for color difference are: First, the problem of potion. The second is the problem of plates.

Make the cape - drill holes - wash - put in the water pool - take out - clean - dry - film.

The color of the board has no color difference, no yin and yang sides, no fingerprints, no sweat stains, and no handprints. No scratches.

Sandblasting uses compressed air as power to form a high-speed jet beam, and sprays sandblasting materials (copper ore, quartz sand, emery, iron sand, sea sand) on the surface of the workpiece to be processed at high speed, thereby changing the appearance or shape of the workpiece surface. Variety.

Sandblasting has powerful applications in engineering and surface technology, such as: increasing the viscosity of bonded parts, cleaning, optimizing surface burrs after machining, and matte finishing of surfaces.

The sandblasting process is more uniform and more effective than manual sandblasting. Stainless steel treatment in this way makes the product low-profile and durable.

Compressed air is used as power to form a high-speed jet beam to spray the spray material onto the surface of the workpiece to be processed at high speed, so that the surface of the workpiece gets the effect of sand grains. There should be no fingerprints, oil stains or sweat stains on the board surface during sandblasting, otherwise they will remain on the surface and cannot be removed after processing.

Change the sand grains - board feeding - clean the board surface - sandblasting - blow off the floating sand on the surface - film.

There should be no uneven sandblasting or yin and yang surfaces on the board surface. There should be no fingerprints, oil stains, etc.

Mirror treatment of stainless steel is a process of polishing the surface of stainless steel to obtain a bright surface like a mirror. Subsequent processes such as titanium plating and etching can be performed.

Stainless steel mirror treatment is just a polished stainless steel surface. Polishing methods are divided into physical polishing and chemical polishing. Partial polishing of stainless steel surfaces is also possible.

The grade of mirror surface can be divided into: 6K, 8K, fine grinding 8K, super fine grinding 8K. The difference lies in the brightness of the surface and the control of the grinding head.

According to the different specifications and thickness: it is divided into manual grinding and machine grinding. Specifications for machine grinding 8K: thickness 0.3-3.0mm, length 1.6 meters to 4.5 meters. Depending on the thickness and processing requirements, the processing prices are different.

There should be no insufficient brightness on the board surface. There can be no grinding flowers. There should be no creases or damage. There should be no residual stains or uneven film on the board surface.

Use a mold to first print the pattern on the surface of the stainless steel plate with ink. Use potion to corrode the stainless steel plate to obtain the desired pattern effect.

Etching is divided into three types: photosensitive etching, silk screen etching, and titanium removal etching.

The principle of film exposure is used to print patterns on the surface of stainless steel plates, which is suitable for making workpieces of irregular length and small batches. Photosensitive etching must be done if the etching depth is above 20 C. Stainless steel can be etched to a maximum depth of 50 C.

Silk screen printing is to print the pattern mold with ink on the stainless steel plate. Use chemical corrosion to corrode the parts that are not coated with ink to form patterns. Silk screen printing is suitable for etching fixed-length and large-volume flat plates. The etching depth is within 3-15C.

There is no depth on the surface, and part of the color is oxidized, causing patterns to appear on the surface of the stainless steel plate.

Printing (coating with ink) - drying - feeding the plate into the machine - corrosion - removing ink - cleaning - drying - film

There are no acid spots, no rotten edges, and no ink on the board surface. It is recommended to use 304 material for etching as much as possible. Reason: The 201 material contains low nickel, the etching position will turn black, it is easy to burn the board, and the service life is short.

The deeper the etching, the harder it is to protect the ink and the more expensive it is.

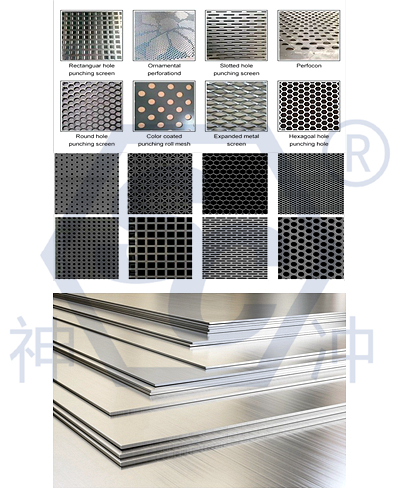

Stainless steel embossed plate is embossed on the stainless steel plate through mechanical equipment, so that a concave and convex pattern appears on the surface of the plate, also called stainless steel pattern plate.

Available patterns include braided bamboo pattern, ice bamboo pattern, diamond pattern, small squares, large and small rice grain boards (pearl pattern), diagonal stripes, butterfly love pattern, chrysanthemum pattern, cube, free pattern, oval pattern, stone pattern, panda pattern, antique checkered pattern, etc.

Patterns can be customized according to customers or can be pressed by our factory. This kind of embossed board has a strong and bright appearance and higher surface hardness. It is more wear-resistant, easy to clean, maintenance-free, resistant to impact, pressure, scratches and does not leave fingerprints. Mainly used in architectural decoration, elevator decoration, industrial decoration, facility decoration, kitchenware and other stainless steel series.

Stainless steel coloring not only gives stainless steel products a variety of colors and increases product variety, but also improves the wear resistance and corrosion resistance of the products.

There are many methods of surface coloring, which are divided into: chemical oxidation coloring, electrochemical oxidation coloring, ion deposition oxide coloring, high temperature oxidation coloring, and gas phase pyrolysis coloring.

The target produces an ionization reaction in the vacuum electric furnace, and then through the injection of gas (oxygen, nitrogen, acetylene), a metallic color film is formed, which adheres to the surface of the stainless steel plate.

Electroplating can enhance the corrosion resistance of metal, increase hardness, prevent wear and tear, improve conductivity, lubricity, heat resistance and surface beauty.

Titanium gold, rose gold, rose red, bronze, black titanium, sapphire blue, emerald green, pink, champagne gold, coffee gold, violet.

Depending on the color, the thickness of the board is different, and the processing price is different. Processable plate specifications: base plate, mirror plate, brushed plate, etched plate, sandblasted plate, patterned plate, combined craft plate. Thickness: 0.3-3.0mm, width: 1000mm, 1219mm, 1500mm, length, variable length can be processed.

Beating - Drilling - Washing - Putting the board on the shelf - Put it in the vacuum oven - Take it out - Take it off the shelf - Film it.

There is no color difference in the stainless steel board surface. There is no yin or yang. No fingerprints, no sweat stains, no handprints. No scratches.

Brushed stainless steel is also called frosted. According to the decoration needs, the common techniques of brushed stainless steel products can be made into straight grain, random grain, linear grain, corrugation and spiral grain. The brushed stainless steel surface has excellent hand feel, delicate luster, wear-resistant surface and unique texture effect. It is widely used in electronic equipment, kitchen appliances and mechanical equipment.

The surface of the stainless steel plate is ground with a high-speed rotating abrasive belt to form regular stripes on the surface of the stainless steel plate.

Ordinary sand, snowflake sand, straight drawing, snowflake sand + ordinary sand, snowflake sand + drawing, snowflake sand + ordinary sand + drawing, ordinary sand + drawing.

The larger the value of the sanding belt, the finer the sand produced. On the contrary, the finer the value of the abrasive belt, the thicker the yarn texture. We usually use No. 320 wire drawing.

Let’s talk about snowflake sand in particular. Snowflake sand is different from other yarn patterns. The surface of snowflake sand has intermittent sand patterns, also called forging patterns, which are ground with a No. 400 sand belt, so it is also called NO4.

The base panels that can be brushed are 2B, BA, and mirror panels. Thickness: 0.4-3.0mm, width: 1000MM, 1219MM, 1500MM. Available as needed. Different thicknesses and different sand patterns result in different processing prices.

Stainless steel spray painting is significantly different from the coloring mentioned above. Depending on the material, some spray paints may damage the surface oxide layer of stainless steel.

But spraying can use a simple process to obtain stainless steel products of different colors, or use different spray paints to change the texture of stainless steel. Just like the stainless steel water cups we use every day, the spraying process is used.

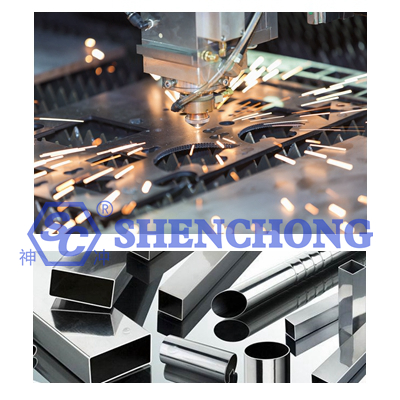

Stainless steel processing technology refers to the process of cutting, folding, bending, welding and other mechanical processing of stainless steel based on the properties of stainless steel to finally obtain stainless steel products required for industrial production. In the process of stainless steel processing, a large number of machine tools, instruments, and stainless steel processing equipment are required.

Many people may have used stainless steel processed products, but everyone is not very clear about the possibilities of its molding process. Next, we will describe 6 different stainless steel processing techniques in detail.

Through mechanical scissors, swing shears, hydraulic shears, CNC shears and other equipment. Cut the stainless steel plate to the required size. The guillotine shearing machine blade material used for cutting stainless steel is Cr12MoV.

Click here to know:

The Ultimate Guide of Shearing Blade Material and Usage

Utilize cutting tools such as laser cutting machine, plasma cutting machine, flame cutting machine...

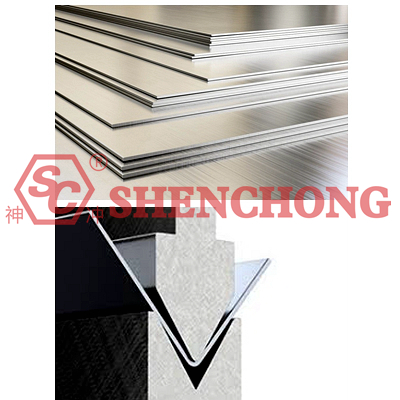

Use manual bending machines, NC hydraulic press brake machines, CNC press brake machines, roll bending machines and other equipment to bend stainless steel and produce curved-shaped components, such as curved pipes, angle irons, etc.

Stainless Steel Bending Related Information:

Bending Quality Control Measures: Stainless Steel and Aluminum

Folding forming technology is a very common processing method in the processing of stainless steel products. Folding is a stamping processing method that uses a mold to turn the hole edge or outer edge of the blank into a vertical edge. When producing stainless steel booths, this process is used to shape stainless steel.

Deep drawing is a stamping process that uses a special mold to make an open hollow part from a flat blank obtained after punching or cutting. Its characteristic is that the sheet material can flow into the concave mold driven by the punch, that is, it relies on the fluidity and elongation of the material to form.

Stainless steel can be joined by various welding methods, including TIG (Tig Welding), MIG (Gas Metal Arc Welding), resistance welding, etc. Welding stainless steel requires special welding materials and operations to maintain its anti-corrosion properties.

Using lathes, milling machines, drilling machines and other mechanical equipment, we perform precise cutting, milling, drilling and other processes on stainless steel to produce precision parts.

The above are the 9 common stainless steel surface treatments and 8 processing techniques. The application and development prospects of stainless steel will become wider and wider, but the application and development of stainless steel largely depends on the development of its surface treatment technology.

Stainless Steel Related Articles:

What Stainless Steel Kitchenware And Kitchen Cabinet Production Process

Stainless Steel Doors And Windows Manufacturing And Characteristic