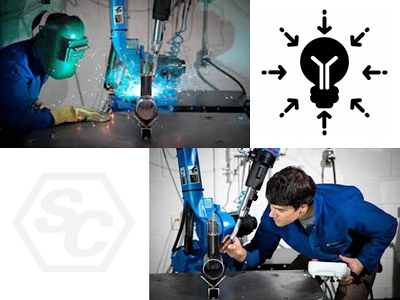

With the continuous improvement of automation and intelligence in sheet metal manufacturing, industrial robots have developed rapidly. In the field of manufacturing, the application of industrial robots is becoming more and more mature.

According to the definition of international organization for standardization, welding robot is one of industrial robots. Robot welding has injected new development power into industry, and will certainly make industrial robots develop more vigorously.

Sheet metal welding robots can easily replace manual welding for perfect welding. They have a high degree of freedom and can be programmed freely to complete fully automated work, reducing the requirements for workers' operation technology and improving production efficiency.

Robot welding can also improve the labor intensity of workers. They can work in a harmful environment to replace many complex jobs that are not suitable for human completion and harmful to health.

Today, let's look at the programming skills and common problems of sheet metal welding robots.

- Select reasonable welding sequence

We need to formulate the welding sequence according to the standards of reducing the welding deformation and the length of the welding torch travel path.

- The space transition of welding torch requires short, smooth and safe moving track.

- Optimize welding parameters

In order to obtain the best welding parameters, the working specimens are made for welding test and process qualification.

- Adopt reasonable positioner position, welding torch posture and welding torch relative joint position

After the workpiece fixed on the positioner, if the welding seam is not at the ideal position and angle, it is required to adjust the positioner continuously during programming to make the welded seam reach the horizontal position one by one according to the welding sequence.

At the same time, the position of each axis of the robot shall be continuously adjusted to reasonably determine the position, angle and wire extension length of the welding gun relative to the joint.

After the position of the workpiece is determined, the position of the welding torch relative to the joint must be observed by the programmer's eyes, which is difficult. This requires programmers to be good at summarizing and accumulating experience.

-Timely insert the gun cleaning procedure.

After a certain length of welding procedure prepared, we should insert the gun cleaning procedure in time. This can prevent the welding spatter from blocking the welding nozzle and the conductive nozzle. Ensure the cleaning of the welding gun and improve the service life of the nozzle.

- Generally, the preparation of the program can not be completed in one step.

We need to constantly check and modify the program during the robot welding process, adjust the welding parameters and the posture of the welding gun, etc., so as to form a good program.

At present, the programming method of welding robot is still mainly based on online teaching. But the programmer's interface has improved a lot from the past. The new welding robot programming interface is more friendly and easier to operate.

- Gun collision

Cause: deviation of workpiece assembly or inaccurate TCP of welding gun.

Measures: check the assembly condition or correct the welding gun TCP.

- In case of arc fault, the arc cannot be started

Cause: the welding wire does not touch the workpiece or the process parameters are too small.

Measures: manually feed the wire, adjust the distance between the welding gun and the weld, or properly adjust the process parameters.

- Protective gas monitoring alarm

Cause: cooling water or protective gas supply is faulty.

Measures: check the cooling water or protect the gas pipeline.

Welding robot is a modern and automatic equipment integrating machinery, computer, electronics, sensors, artificial intelligence and other aspects. Welding robot is mainly composed of robot and welding equipment.

- Welding deviation

Cause: the welding position is incorrect or there is a problem when the welding gun looks for the position.

Measures: consider whether TCP (welding torch center point position) is accurate and adjust it.

If this happens frequently, check the zero position of each axis of the robot. Recalibrate and correct.

- Undercut

Cause: improper selection of welding parameters, incorrect angle or position of welding gun.

Measures: appropriate adjustment.

- Air hole

Cause: poor gas protection, too thick primer of workpiece or insufficient drying of protective gas

Measures: it can be solved by corresponding adjustment.

- Excessive splashing

Cause: improper selection of welding parameters, gas composition or too long extension length of welding wire

Measures: properly adjust the power of the machine to change the welding parameters. Adjust the gas proportioner to adjust the proportion of mixed gas. Adjust the relative position between the welding torch and the workpiece.

- There are arc pits at the end of the weld after cooling

The function of submerged arc pit can be added in the working step when programming, and it can be filled.

With the rise of human cost, the automation and intelligent production of sheet metal processing industry has become the general trend. The expansion and wide application of welding robots in the field of construction machinery have greatly improved the overall production efficiency, improved the working conditions of welding workers, and improved the flexible level of welding production and welding quality.

At the same time, it also promotes the automatic upgrading of welding related fields, such as sheet metal bending, shearing, rolling, etc. It is expected that industrial robots will develop in the direction of virtual reality technology, multi-sensor information fusion technology, multi-agent robot system and mobile robot system in the future.