Technological progress has greatly changed the face of every industry, especially in the past few years. With the development of the times, more and more enterprises have begun to embark on the road of factory automation, and there is an increasing demand for sheet metal storage warehouses.

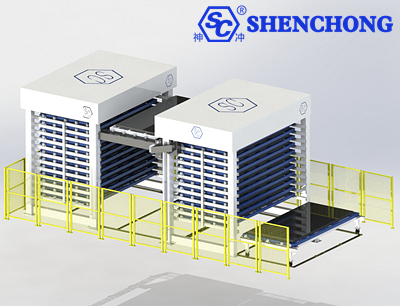

Double row sheet metal storage system is an efficient storage system with characteristics such as precise positioning, stable operation, and fast and flexible operation. These characteristics undoubtedly make the double row sheet metal storage system unique in the field of warehousing.

The double row sheet metal storage system adopts rectangular tube assembly to form, and the lifting column is processed by a gantry milling machine to ensure the accuracy and stability of operation.

The lifting mechanism of the double row sheet metal storage system adopts a well-known Chinese brand motor, which is driven by a double row chain to lift the tray plates. The tractor mechanism on the lifting machine pulls the hook on one side of the tray to achieve entry and exit of the warehouse. The overall structure is simple and elegant, and the equipment is easy to disassemble and move.

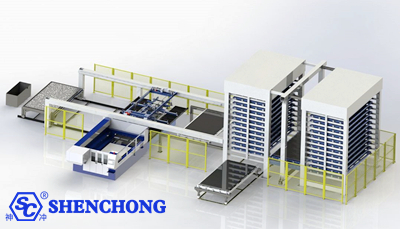

The front/side feeding and discharging system of the double row sheet metal storage system is another important component. It is formed by welding rectangular tubes, and the material is placed into the tray by a hydraulic lifting mechanism. The motor drives the tray to walk on the truss crossbeam, completing the feeding and discharging of materials at the bottom of the sheet metal storage system. This system can quickly put materials into the sheet metal storage system and accurately control the quantity of materials on each tray.

Roller pallets are another important equipment in the double row sheet metal storage system. It is formed by welding rectangular tubes and optimized through tray finite element analysis, with high load-bearing capacity and stability. Install positioning pins on the tray for plate loading and positioning. At the same time, there are two pull blocks with U-shaped notches on both sides of the tray. When the translation device moves, the irregular pull blocks will hook the U-shaped notches on the tray, achieving the entry and exit of the tray.

The electrical control system is the brain of the entire double row sheet metal storage system, which is controlled by Siemens PLC and Weilun touch screen. It includes interfaces such as board storage, board outbound, board loading, board unloading, incoming and outgoing material record statistics, inventory quantity statistics, inventory warning, and fault warning prompts. The Chinese interface is simple and convenient to operate, making it easy for operators to learn and understand.

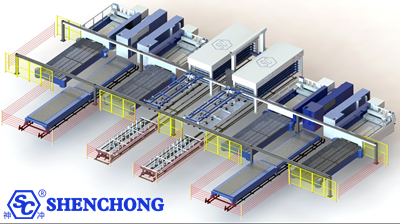

Each structure of the double row sheet metal storage system is carefully designed to provide an efficient, accurate, and stable inbound and outbound system. This system can greatly improve the efficiency of warehouse management, reduce waste of manpower and material resources, and meet the efficient needs of modern warehousing.

The automatic double row sheet metal storage system can store your materials in two separate columns, saving more space. The access points of the double row sheet metal storage system can be located on both sides of the system, making the loading and unloading of large items more convenient, efficient, and ergonomic. The double row sheet metal storage system can save time and reclaim valuable ground space.

The maximum length of each pallet in the automatic storage system of the double row sheet metal storage system can reach 12 meters, and the maximum load capacity of each pallet can reach 8000kg. Capable of storing sheet metal, sheet metal, bars, pipes, frames, panels, pallets, tools, and other heavy or atypical metal, plastic, or wood items.

Our Wuxi SHENCHONG automated storage system provides efficient storage and protection of goods. The double row sheet metal storage system can appropriately protect vulnerable components and reduce cargo loss. The system also significantly improves the safety of working conditions in storage system or production workshops. The double row sheet metal storage system can also control all storage operations, goods delivery, and inventory in real-time.

- Easy to use and customize. Very suitable for creating fast, precise, reliable, and multifunctional production units. Provide shorter production cycles.

- The automatic sheet metal loading, unloading, sorting, and stacking system will make your sheet metal processing auxiliary processes faster and more convenient.

- The intelligent double row sheet metal storage system has a compact structure, saves space, and cleverly designed to increase flexibility and reduce footprint in already crowded production environments.

- The double row sheet metal storage system can be integrated with the internal ERP/WMS system of the factory, as well as other warehouse equipment such as forklifts, stackers, cranes, robotic arms, fiber lasers, or water knives, making the work of these factories easier.