Safety is an important measure when doing any task, and especially so when operating heavy machinery. Also, the press brake safety is a hot topic.

A press brake is a powerful piece of equipment. If used improperly, or without the right training, accidents and injuries can happen.

Press brakes range in size and method of function, but safety is one of the main aspects that does not change. Accidents can lead to injuries, unwanted time off work, a prohibition from operating your assigned task, removal from press brake operation, or even loss of a job.

Negligence is something that many companies take seriously. Proper training and assessments are put into place to protect the operator and the company.

Press brakes can face several issues. For instance, hydraulic press brakes can have oil leaks, overheating, loss of pressure, and general neglect of the machine.

Some common workplace issues that can lead to safety concerns are:

– Ram dropping, and crushing whatever is under the ram, can be a result of pressure failure.

– Sharp metal, projectiles, or pressurized hydraulic fluid can lead to serious injuries like lacerations or puncture wounds to the operator.

– Fittings can become cracked or loose and rupture. A hose can become detached.

– The pressure can cause the metal to crack and eject jagged pieces.

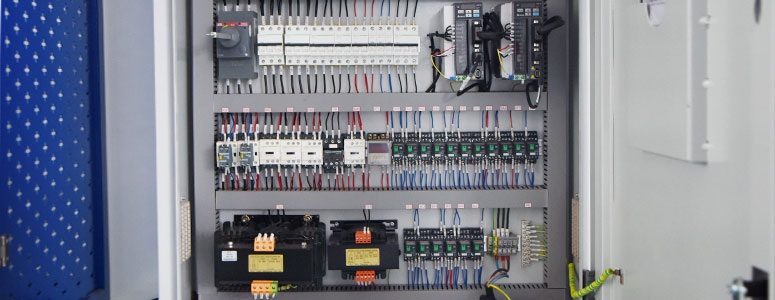

– System malfunctions like reading errors, electrical failures, wiring issues, system locks, and other issues can cause safety problems in electric press brakes.

The best measures for press brake safety:

– Inspection: Perform thorough inspections regularly. Check for damage to seals and hoses, leaks, cracks or wear on the general machine body, cracks or tight fits in fittings, and dirt or fluid degradation.

– Listen: When operating a press brake listen for strange noises. Excessive vibrations or strange noises can indicate a need for immediate repair.

– Cleanliness: Safety and proper operation of the machine are aided with adequate lubrication of the hydraulics. Dirt, slick oil, or clutter can cause severe issues.

– Maintenance: Consistent upkeep of the machine is crucial to maintaining safety. Press brakes are intensive machines and require a watchful eye.

– Training: Any operator of a press brake must be knowledgeable in all areas of operation. Proper precautions must be adhered to.

Press brakes are outfitted with several safety measures to protect the operator and the machine. Safety is a key focus in the development of press brakes and should be taken seriously during operation.

Movable guards are placed on the sides of the machine. These guards reduce the risk of the operator having their hands or fingers pinched when the operator reaches between the punch and die, or between the back gauge and tool.

There are also rear guards to prevent entry from the rear of the machine. Rearguards reduce the risk of hands or fingers being pinched between the punch and die or being impacted by the back gauge. Rearguards also help to protect operators other than the auxiliary or main operator.

The front of the point of operation has light beams projected at it. If an obstruction interrupts the light beams during the ram stroke, the ram will stop. The ram doesn’t stop during the opening process because the obstruction interrupts the light beam.

To maintain a safety distance, the light curtain should not be used when bending small parts and parts with longer side flanges, unless the function is muted. It is necessary to provide auxiliary light beams if the operator is likely to reach between the main light beams and the front edge of the bed.

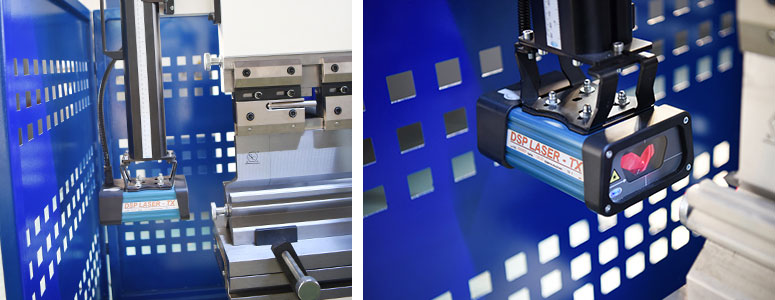

Laser beams are projected between the punch and die at the point of operation, usually two or more laser beams. If an obstruction interrupts the laser beams during the ram closing process, the ram stops. The ram will not stop during the opening process because the obstruction interrupts the laser beams.

Just below the punch is where the laser beams are located. The laser beam device can be used when bending small parts and parts with long side flanges. The ram decelerates to a speed of 10mm/s or less when the ram comes to the mute point.

Know more about Press Brake Laser Protection

When the press brake will not be in operation, the operator should open the door and power the machine off. This will let others know that the press brake machine is not in use and will present the ability to see into the machine to know that it is free of clutter.

It should always be assumed that if the door is closed on a press brake, that the machine is in use and should be treated as such. A press brake machine should not be left idle with the power on while an operator is not present.

The proper safety signs should be displayed on the machine in visible areas. Signs that warn of possible injury to hands and fingers should be present in areas that are easy to notice. Signs that tell the operator of the presence of light beams or laser beams to ensure safety should be visible.

Safety signs are important to ensure that the operators are knowledgeable of the safety precautions being taken for the machine and for the operators to have a reference to understand what safety measures each press brake has.

Safety is a primary concern for anyone operating heavy machinery. Companies must provide proper training and instruction so that the operators are prepared as best as possible to complete their assigned tasks.

Keeping a clean and functioning workstation is crucial to the safety of a press brake and the operator. Operators using press brakes that are outfitted with light beam or laser beam protection must be aware of that safety measure to ensure that the beam-ways stay free of debris or obstructions.

Safety signs will warn operators of the hazards a press brake has. Performing proper and consistent maintenance by both the operator and the employer will lead to a safer work environment.