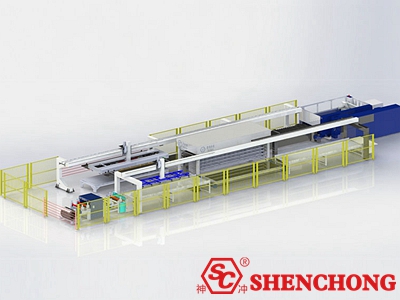

Light Pole Production Line provides you with numerous flexible solutions, suitable for diversified pole products. The street light pole production line equipment is not only suitable for street light poles, but also suitable for the production of sign poles, flag poles and high pole lights.

Street lamps are important infrastructure facilities in cities. With the acceleration of urbanization, their demand is growing. The lamp pole is the main part of the street lamp, and its production line belongs to the mass, multi variety and multi process manufacturing mode. Its processing and manufacturing are affected by many factors.

The light pole production line includes the following processing technology.

It is mainly to unfold, level and cut the steel coil into the required size. The system consists of six parts, including uncoiler, side guide device, leveling machine, plate shearing machine, stacking device and electrical system. It is especially suitable for the leveling of street lamp poles, flag poles and other pole equipment.

It is suitable for longitudinal cutting of long shearing plates. The length of the sheared sheet can be adjusted at will. It has high labor productivity. The plates to be sheared are pressed onto the traveling device by hydraulic steel. The plate is sheared with the running of the traveling device.

When pressing, the plates shall be placed at an angle according to the required size, which can shear the tapered plates. It is especially suitable for cutting the boards of light poles and flag poles.

This equipment consists of two plate bending machines. Tandem CNC Press Brakes are linked to realize synchronous work. The light pole press brake machine is equipped with different molds, which can be used to produce street light poles, flagpoles, high pole lamps, etc.

When it is used for the production of conical lamp poles, the conical mould is installed. When multi steps bending is performed, the last step completes the middle bending, and a conical lamp pole is formed. Then pull out the lamp pole with the lamp pole rolling machine.

When polygonal light posts, marker posts and high pole lamps need to be produced, special polygonal bending tools can be installed.

You can click here for more information about Tandem Press Brake Purchase Guide

The equipment is composed of a host head, a traction bed and a waiting row cover. The traction bed is moved by the traction chuck on the moving trolley to clamp the steel big head trolley, and the steel rod is driven to move from the small head to the big head. It moves at a constant speed under the clamping of six clamping jaws of the main engine head. The big end of the steel rod is hijacked by the loose steel rod trolley, and the guide wheel on the machine head realizes automatic butt joint. When the steel rod is seamed, the welder starts to undulate welding.

This equipment adopts automatic welding. Automatic recovery of flux. The weld is even. Continuous and beautiful. Strong penetration. Joint welding is formed at one time. High welding efficiency. The equipment is mainly used for welding street lamp poles and flag poles.

The equipment is simple, compact and convenient. During specific operation, the steel rod can be placed on the die manually. Manual holding, hand-held, button point dynamic pressure type. Straightness of steel pole shall be controlled by manual visual inspection. Efficient.

The equipment can be used to straighten road light poles, marker poles, flag poles and high poles of any shape.

According to the design requirements, the head of some street lamp poles needs to be bent. The pipe bender is composed of main board and bending die. Two sets of molds will be equipped. When the straight die is cleaned by the reducer, the steel pipe pressed on the round die is bent along the round die.

Simple operation. No heating and fillers are required. The upper part of the tapered street light pole can be bent directly. economical and practical. It is a necessary equipment for light pole manufacturers.

According to the different needs of users, we can provide the most economical and applicable complete light pole production line, flagpoles, power poles, communication tower poles and wind power poles. According to the different needs of customers, design special sheet metal automation production lines for customers. Only need to provide relevant parameters, and we will design and lay out the overall layout for you to ensure that they can produce qualified products!