Frame hydraulic press, also known as single column hydraulic press. The appearance of the hydraulic press is "frame type". It is a type of hydraulic oil that uses specialized hydraulic oil as the working medium and a hydraulic pump as the power source. The hydraulic oil enters the oil cylinder/piston through the hydraulic pipeline through the force of the pump, and there are several sets of mutually matched seals in the oil cylinder/piston. The seals in different positions are different, but they all play a sealing role, preventing the hydraulic oil from leaking. Finally, the hydraulic oil is circulated in the oil tank through a one-way valve, causing the cylinder piston to cycle and perform work, thereby completing a certain mechanical action as a form of productivity machinery.

The main related structure of the hydraulic press is composed of two parts: the main engine and the control mechanism. The main engine of the hydraulic press includes the body, main cylinder, ejection cylinder, and filling device. The power mechanism consists of a fuel tank, a high-pressure pump, a low-pressure control system, an electric motor, various pressure valves, and directional valves. Under the control of electrical devices, the power mechanism operates through pumps, oil cylinders, and various hydraulic valves.

Control valve: controls the flow, direction, pressure of hydraulic oil, the working sequence of hydraulic actuators, and protects the hydraulic circuit. Simply put, it controls and regulates the flow, pressure, and flow of hydraulic media, thereby controlling the direction of movement, output force or torque, speed, and sequence of action of the actuator, as well as limiting and adjusting the working pressure of the hydraulic system to prevent overload and other effects (such as one-way valves, directional valves, relief valves, pressure reducing valves, sequence valves, throttle valves, speed regulating valves, etc.).

Hydraulic pump: a conversion device that converts mechanical energy into hydraulic energy.

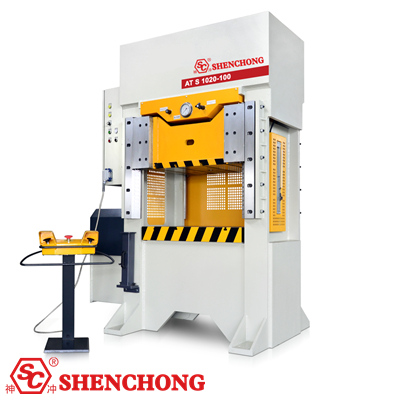

The most significant structural feature of a frame type hydraulic press is its integral steel plate welded frame type frame. This design gives hydraulic presses extremely high overall rigidity and compressive strength.

Specifically, the upper crossbeam, slider, and worktable of the frame hydraulic press are all welded with high-quality steel plates, and welding stress is eliminated through high-frequency vibration to ensure the stability and durability of the body structure. At the same time, the column is made of high-quality 45 # steel, with a surface medium frequency quenching and chrome plating treatment, further improving its bending resistance and wear resistance. This structure enables the frame hydraulic press to withstand larger working loads, ensuring stable operation under complex working conditions.

The hydraulic pump is the power source of the hydraulic system, which relies on the force of the pump to allow hydraulic oil to enter the oil cylinder/piston cylinder/piston through the hydraulic pipeline. There are several sets of mutually matched seals in the oil cylinder/piston, and the seals in different positions are different, but they all play a sealing role, preventing hydraulic oil from leaking.

Finally, the hydraulic oil is circulated in the oil tank through a one-way valve to circulate the oil cylinder/piston for work, achieving energy conversion, regulation, and transportation, and completing the circulation of various process actions.

Hydraulic cylinder: Transforming hydraulic energy into mechanical energy. Hydraulic transmission is a transmission method that uses liquid pressure to transmit power and control. The hydraulic device consists of an hydraulic pump, hydraulic cylinder, hydraulic control valve, and hydraulic auxiliary components.

Adopting an integral steel plate welded frame type frame, with good overall rigidity and high compressive strength. Pressure, stroke, pressure holding, etc. can be adjusted according to the requirements of the pressing process. It has different derivative models such as lower top material, upper item material, upper and lower composite top material, or shallow drawing, suitable for various pressing and forming processes.

After mold closing, the pressure rises quickly and reaches the rated pressure in just a few seconds. Adopting a bottom mounted fuel tank, it is convenient to replace and clean the fuel tank. After more than ten years of mass production, the quality is stable and the performance is reliable.

Frame work hydraulic presses have significant advantages in energy conservation. Its hydraulic oil consumption is generally only about 50% of that of traditional hydraulic presses, while saving 50% -70% electricity. This is mainly due to its optimized hydraulic and electrical control systems, which make energy utilization efficiency higher. In addition, the speed of frame hydraulic presses can be greatly improved, and the working rhythm is several times higher than traditional hydraulic press machines, thereby improving production efficiency.

The pressure, speed, and position of the frame hydraulic press are all fully closed-loop digital control, with high degree of automation and accuracy. Its pressure and speed are programmable to meet various process needs, and can also achieve remote automatic control. This high degree of automation not only improves production efficiency, but also reduces the skill requirements for operators and reduces the impact of human factors on product quality.

The noise level of frame hydraulic presses is generally less than 70dB, far lower than that of traditional hydraulic presses. This is mainly due to its optimized hydraulic system and structural design, which reduces the vibration and noise during machine operation. A low-noise working environment is beneficial for protecting the hearing health of operators and improving work comfort.

The maintenance of frame hydraulic presses is relatively simple and convenient. It adopts a bottom mounted oil cylinder design, making it easy to replace and clean the oil cylinder. At the same time, the cleanliness requirements of hydraulic oil are much lower than those of hydraulic proportional servo systems, reducing the impact of hydraulic oil pollution on the system. This makes the frame hydraulic press have lower maintenance costs and higher reliability during long-term use.

Stamping, forming, shallow drawing, shaping, and pressure assembly of metal or non-metal parts. Pressing of glasses, locks, and hardware components, electronic connectors, electrical components, motor rotors, stator pressing, etc.

The processing of spare parts in the automotive industry, as well as the shaping, edging, calibration, and pressing of various products in various industries such as shoes, handbags, rubber, molds, shafts, and sleeves, as well as the bending, pressing, and stretching of sheet metal parts, washing machines, electric motors, automotive motors, air conditioning motors, micro motors, servo motors, wheel manufacturing, shock absorbers, motorcycles, and machinery.

Frame hydraulic presses are widely used in industries such as metal processing, plastic molding, rubber products, powder metallurgy, ceramic products, glass products, etc. Specifically, it can be used for processes such as stretching, stamping, punching, bending, and flanging of metal sheets; It can also be used for pressing, cutting, punching and other processes of non-metallic materials. Frame hydraulic presses play an important role in fields such as automotive manufacturing, home appliance manufacturing, and aerospace.

With the transformation, upgrading, and intelligent development of the manufacturing industry, frame hydraulic presses will face greater development opportunities and challenges. In the future, frame hydraulic presses will develop towards greater efficiency, energy conservation, environmental protection, and intelligence. Specifically, the following aspects will be the focus of future development:

By optimizing the hydraulic system and electrical control system, further improve the energy utilization efficiency of frame hydraulic presses and reduce energy consumption costs.

Strengthen the application of intelligent technology, achieve higher levels of automation and intelligent control, improve production efficiency and product quality.

Continuously developing new processes and products, expanding the application areas and market prospects of frame hydraulic presses.

Pay attention to environmental protection and sustainable development, adopt environmentally friendly materials and energy-saving technologies, and reduce environmental pollution and energy consumption emissions.

In summary, as one of the important equipment in modern industrial production, frame hydraulic presses have significant structural characteristics and performance advantages.

In future development, with technological innovation and changes in market demand, frame hydraulic presses will continue to play an important role and continuously expand their application fields and market prospects.