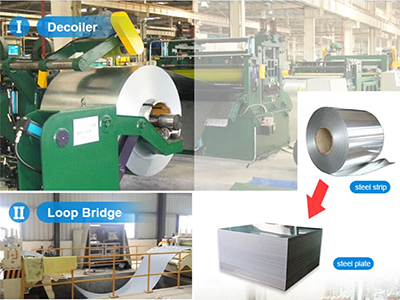

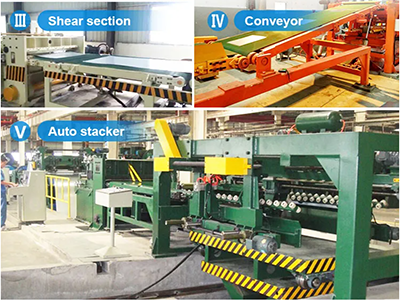

The CNC cut to length production line that can be deployed butting edge function is used to uncoil, straighten, and cut CR coils, stainless steel coil, zinc galvanized plates, and color coated plates to various plates with special sizes.

Standard devices consist of charging cart, decoiler, material feeding machine, position limited device, transition working table (edge cutting machine, slice coiler), straightening master motor, size-forming working table, tail plate feeding machine shearing machine, transition working table, pneumatic discharging frame, settling cart, hydraulic system, and electro-pneumatic system.

The main units of the hydraulic system in the automatic cut to length line adopt the high precise components from Taiwan. The electro-pneumatic system adopts import PLC controller and touch-sensitive screen to control all the function. Meanwhile, the straightening master motor uses DC motor, and DC controller from Eurotherm Corp, which has many advanced features such as automation, good quality of straightening, high precision of shearing and cutting, reliable and stable function, easy operation and maintenance etc.

Intelligent Manufacturing Redefine Your Future!

Item | Unit | Size |

Thickness | mm | 1-4, 1.5-6, 2-8, 2-10, 3-12, 4-16 |

Width | mm | 1550, 2000, 2200 |

Capacity | t | 20, 35 |

Flatness | mm/m^2 | ≤2.0-2.5 (standard plate) |

Length Tolerance | mm/2m | ≤±1.0 |

Line Speed | m/min | 0-25 |

Total Power | kW | 85-250 |

Also welcome to check with our related products:

Front Feeding Hydraulic Shearing Machine

This CNC cut to length line is mainly used for uncoiling, leveling and shearing of aluminium girth sheets with edge-cutting function, which is necessary for the leveling of aluminum screen wall, and also specially suitable for cold sheets. The mirror surface applies high precision leveling of stainless steel.

Standard allocation consists of charging wagon, decoil, supporting plate pressure ram device, material feeding device, pre-calibration, storage bin, limiter, sextuplet type precision leveling machine, film device, shearing machine, conveying working platform, pneumatic layout support, hydraulic lift platform, discharging working platform, hydraulic system and electric control system.

The main component of hydraulic system in this cut to length production line applies high precision component parts from Taiwan. The length system is controlled by positioning servo system from German Lenze company. The electric control is controlled full line by PLC program and touch screen. It has such characteristics as high automatic, good leveling quality, high shearing precision, high production efficiency, steady and reliable performance and easy operation and maintenance.

Item | Unit | Size |

Thickness | mm | 0.3-1.5, 1.0-4.0, 2.0-6.0 |

Width | mm | 1000, 1250, 1550, 1900 |

Capacity | t | 12, 20 |

Flatness | mm/m^2 | ≤1.5 (standard plate) |

Length Tolerance | mm/2m | ≤±0.50 |

Line Speed | m/min | 0-25,60 |

Total Power | kW | -45, -60, -70, 85 |

Q: Do you provide customized?

A: Sure, we are professional cut to length line manufacturer and we can design the equipment according to the data of the structural section you provide.

Q: Do you have after sales support?

A: Yes, we are happy to give advice and also have skilled technicians available to maintain the machine if needed. As an experienced cut to length line factory, we can provide you online service, such as video training first, and if you need oversea help, we can also provide oversea engineers after sales service.

Q: Why your cut to length price is higher than others?

A: As we persist on that each factory should put quality at the first place. SHENCHONG spend time and money on developing how to make machines much more automatic, accurate and high quality. We can make sure that our cut to length machine could use more than 20 years without any problem.

Q: Can you be responsible for transport?

A: Yes, please tell us the destination port or address. we have over 20 years experience in international transport.