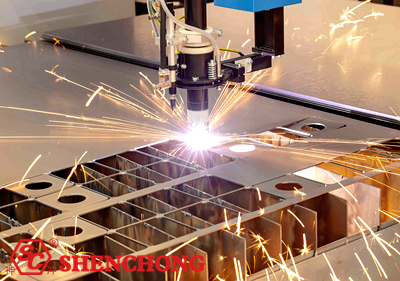

The principle of cnc plasma cutting machine is a cutting technology that uses high temperature, high energy and high speed of plasma to cut metal materials. Plasma is a charged gas composed of electrons and ions. Its temperature can reach tens of thousands of degrees and its energy density is extremely high. It can instantly heat metal materials above the melting point to melt them and form an oxide layer. The molten metal material is blown away, enabling cutting.

Plasma is a gaseous state in a high-energy state with properties such as ionization, conductance, and radiation. In a plasma, electrons of gas atoms collide with ions, releasing energy and ionizing the gas atoms into positively charged ions and negatively charged electrons. When the electrons return to the ground state of the atoms, they emit photons and heat, creating a plasma.

Plasma cutting machines are widely used in industrial fields such as metal cutting and welding. Its application range includes cutting and welding of stainless steel, aluminum alloy, copper, brass, steel and other materials. Plasma cutting machine can achieve precise cutting and welding, with fast cutting speed, high efficiency and good effect. Therefore, it is widely used in metal manufacturing, machinery manufacturing, automobile manufacturing, construction engineering and other industries

The cnc plasma cutting machine introduces oxygen and inert gases (such as nitrogen, argon, etc.) into the cutting head through the gas introduction system, and then ionizes the gas through high-frequency arc ignition.

After the arc is ignited, the molecules in oxygen and inert gas are decomposed into ions and free electrons to form plasma. The temperature of the plasma can reach tens of thousands of degrees, and the energy density is extremely high, which can instantly heat the metal material above the melting point.

The high temperature and high energy in the plasma act on the metal material, causing it to melt and form an oxide layer. The oxide layer plays a role of heat insulation and protection, preventing the metal material from being further heated and oxidized.

The plasma blows away the molten metal material through a high-speed airflow to achieve cutting. The inert gas in the gas plays a protective role to prevent the molten metal material from being oxidized.

Plasma cutters can cut metal materials quickly, because the high temperature of the plasma can quickly melt the surface of the material. This high efficiency makes the plasma cutter an efficient metal cutting device.

Plasma cutters can cut shapes with high precision, because the high temperature of the plasma can melt the surface of the metal material and form smooth edges. This high precision makes plasma cutting machines ideal for manufacturing high-precision metal parts.

Click here to know High-precision CNC Shearing Machine For Sale

The cost of a plasma cutter is relatively low because it does not require the use of expensive laser or waterjet cutting equipment. This low cost makes plasma cutters an affordable metal cutting device for small to medium businesses and personal use.

When using a plasma cutting machine, you need to pay attention to the following points:

When using a plasma cutting machine, you need to wear protective clothing, gloves, masks and other protective equipment to avoid sparks, oxygen explosions and other hazards.

When using a plasma cutting machine, it is necessary to reasonably adjust gas flow, air pressure and other parameters to ensure cutting quality and efficiency.

Different metal materials need to choose different plasma cutting machines to ensure the cutting effect and service life.

CNC plasma cutting machines need regular maintenance, cleaning of various parts, and replacement of worn parts to ensure cutting quality and service life.

Plasma cutting machine is a kind of equipment that uses plasma high energy density and instantaneous high temperature melting metal technology for cutting, welding and surface treatment. The principle is to use the high energy density and instantaneous high temperature of plasma to melt metal materials, so as to realize cutting, welding and other processes.

Plasma cutting machine is widely used in metal manufacturing, machinery manufacturing, automobile manufacturing, construction engineering and other industries, because it can achieve precise cutting and welding, fast cutting speed, high efficiency and good effect. When using a plasma cnc cutting machine, it is necessary to pay attention to safe operation, gas adjustment, material selection, maintenance and other aspects to ensure cutting quality and service life.