The bending robot workstation uses the robot to communicate with the CNC press brake to form an automatic bending production unit.

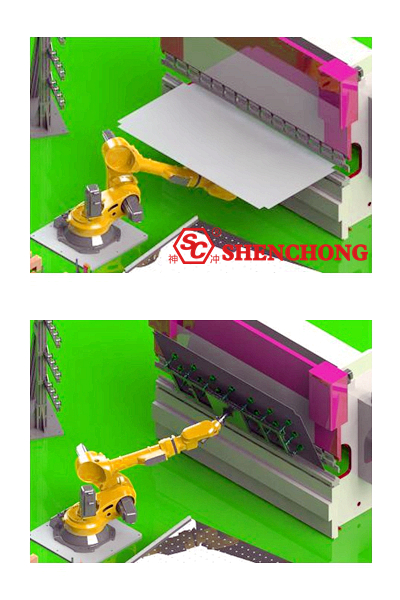

The bending robot uses the gripper to grasp the sheet metal and cooperate with the press brake machine program to follow the sheet metal track to realize automatic bending.

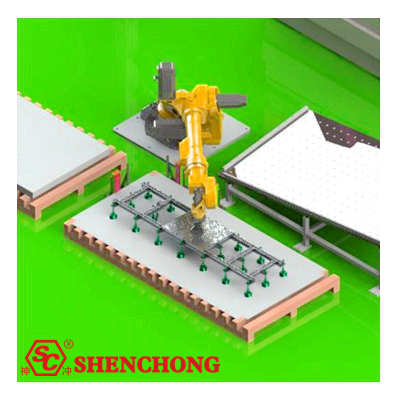

The robot bending workstation is composed of a CNC press brake, a robot, a feeding system, a gripper system, a centering system, an automatic aligning system for the rear gear finger, etc. It can save manpower, reduce production costs, and ensure the consistency of bending workpiece. At the same time, it will help improve the corporate image and competitiveness to a higher level. The robot bending machine can work 24 hours without interruption, working hard, on call, safe and low cost.

The robot grabs the sheet at the feeding position. It is mainly detected by the sensor on the fixture.

The robot will first place the plates grabbed from the feeding position on the centering table. Under the action of gravity, the plate slides to the position with the lowest height on the centering platform. The robot grasps the workpiece again to ensure the consistency of each grab.

The robot grasps the workpiece close to the rear positioning device of the cnc press brake machine. In the process of approaching, the robot slides along the lower die. When the rear positioning sensor is triggered, the workpiece is in place. The robot controls the press brake for bending.

The robot puts one side of the bent workpiece on the exchange platform and rotates the fixture 180 degrees, and then grabs the workpiece again.

The automatic bending robot working unit is a high-tech that integrates three technologies of precise positioning, uniform feeding, and high-precision follow-up bending. The bending robot, a high-tech system integrating three technologies, realizes unmanned operation and automatic flow production. Save manpower, improve safety and efficiency. The current bending robot is an automation equipment specially developed for the press brale bending step, with high professionalism and high automation integration.

Compared with manual labor, the advantages of bending robot workstation are reflected in three aspects: efficiency, safety and quality. The efficiency and safety advantages are obvious. The advantages in quality are mainly reflected in two aspects. First, the positioning of the bending robot is accurate and repeatable. The second is that the good clamping effect eliminates wrinkles.

With the rise of human cost, the demand for the application of automatic bending robot is increasing. In the past, bending has been affected by factors such as long teaching time and great tracking difficulty, which cannot be popularized.

With rich experience in sheet metal processing automation and bending process, Wuxi Shenchong has continued to explore and develop in the field of automatic bending. According to the actual bending work pieces of customers, we design and manufacture loading frame, positioning table, turnover frame, robot gripper, blanking frame and other auxiliary devices, so that customers can realize the automation of sheet metal processing. It has received a very good response from customers who have used it.

In the process of sheet metal processing, because the edge of sheet metal is very sharp, workers are often injured. Especially when processing large sheet metal parts, it not only requires the cooperation of multiple workers, but also has the potential safety hazard of worker injury. At the same time, we should also take into account the problem that the workers are exhausted after a long time, which affects the precision and quality of products.

The integration of positioning, feeding and bending of the sheet metal robot not only eliminates all the above hidden dangers, but also has the advantage of continuous 24-hour non-stop work. Robots liberate manual labor, improve efficiency and save costs. The one-time investment is large and the later maintenance cost is low.

Nowadays, the bending robot has been successfully applied in electrical cabinet industry, elevator industry, filing cabinet, oven, kitchen utensils and other fields. As long as there is a need for sheet metal bending, the robot can greatly improve its bending efficiency and quality.

Robots can not replace all work at this stage. However, some dangerous and complex jobs, such as the handling, turnover and processing of large-sized sheet metal parts in the bending machine, have been replaced by automatic bending robots, which require multiple labors. It is believed that in the near future, the application field of the sheet metal bending robot will be more and more extensive, and people's life will become easier and easier.