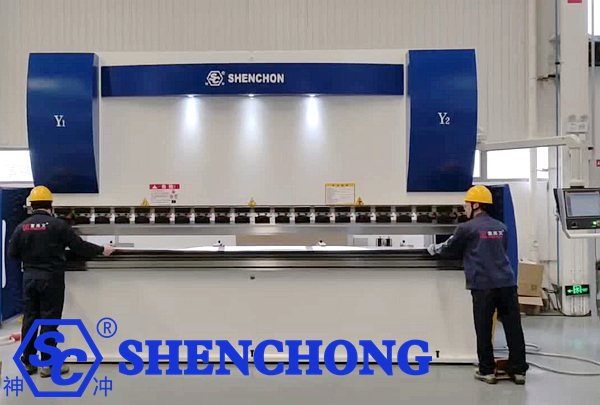

In the construction industry, WSK CNC press brake machine is an extremely important sheet metal processing equipment, widely used for precision bending, forming and angle processing of building components, suitable for various types of steel structures, curtain wall panels, bridge components, etc. The following is an introduction to Construction Industry CNC Press Brake WSK 160T 4500MM 4+1 axis EL15T.

Nominal pressure: 1600 kN (160 tons)

Bending length: 4500 mm

Number of controlled axes: 4+1 axes (Y1, Y2, X, R axes + V axis compensation)

Control system: EL15TSC CNC system

Drive system: Servo motor drives the main oil pump, closed-loop control

Energy saving effect: Compared with traditional electro-hydraulic bending machines, energy saving can reach 60%

Noise level: About 25 decibels during standby and fast operation, low noise

Oil temperature control: The oil temperature is stable, suitable for long-term continuous work

Synchronous control: Y1 and Y2 axes are closed-loop synchronously controlled through the servo electro-hydraulic system

Back gauge system: X axis controls the front and rear positions, and R axis controls the up and down positions to ensure bending accuracy

Workbench compensation: V axis (hydraulic or mechanical ) Automatic compensation to ensure the consistency of bending angle

Body structure: All steel plate welding, tempered and vibration aging treatment, eliminate internal stress, ensure long-term stability

Processing accuracy: The frame adopts imported CNC machining center for one-time clamping processing to ensure the parallelism and verticality of each mounting surface

Guide rail system: High-precision ball screw and linear guide rail are used to ensure movement accuracy and stability

Electrical components: International brands are used to ensure the reliability of the electrical system

Energy-saving design: The main oil pump only runs when needed under the drive of the servo motor, reducing energy consumption and heat generation

Steel structure component bending (H-beam/channel steel/plate edge bending)

Curtain wall aluminum plate, bridge guardrail, column, lamp pole manufacturing

Stainless steel door frame, window cover, elevator plate edge bending

Distribution cabinet, air duct, cabinet and other large plate processing

Bending I-beams, channel steels, angle steel edge sealing

Making steel beam edging, steel column guard plates, etc.

Precisely control angles to ensure error-free welding and assembly

Advantages: Multi-angle processing can be achieved without mold stamping, suitable for customized component production

Processing aluminum veneer, stainless steel decorative panels, honeycomb panels

Folding curtain wall edging, corners, keel cover

Can accurately control the bending angle and seam accuracy

Advantages: High-end building facades have high aesthetics and high consistency of finished products

Processing guardrail closures, windshields, protective covers

Making box beam side panels, connecting steel plate corners, etc.

Folding to strengthen the structural strength of components

Advantages: Improve the bending stiffness and assembly efficiency of bridge components

Metal formwork edging (such as floor slabs, wall panel steel formwork)

Processing cable troughs, pipeline troughs, corner brackets, etc.

Making reinforced frames , positioning folding and other parts

Advantages: Suitable for mass production of metal parts in industrialized buildings (prefabricated buildings)

Bending elevator decorative panels, car panels, door frame

Bending aluminum alloy door and window profile frames

Making distribution cabinet shells and metal junction boxes

Advantages: Improve the appearance of neatness and assembly accuracy, and adapt to the processing of various thickness plates

Improve efficiency: Batch bending, shorten construction period

Ensure accuracy: CNC controls angle errors and has high assembly accuracy

Reduce costs: Flexibly respond to the processing of various components

Strong adaptability: Can process a variety of materials such as carbon steel, stainless steel, and aluminum plates

Intelligent operation: CAD import, 3D simulation, automatic compensation, reduce dependence on technicians

If you are engaged in building sheet metal processing, steel structure production or on-site component assembly, SHENCHONG press brake machines can greatly improve your production flexibility and component quality.