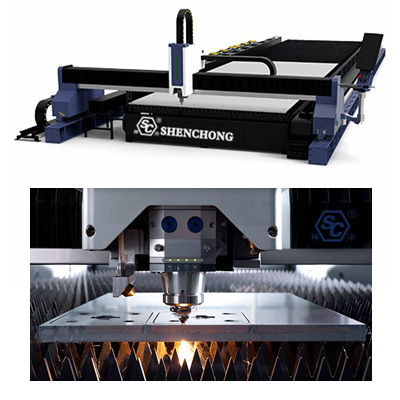

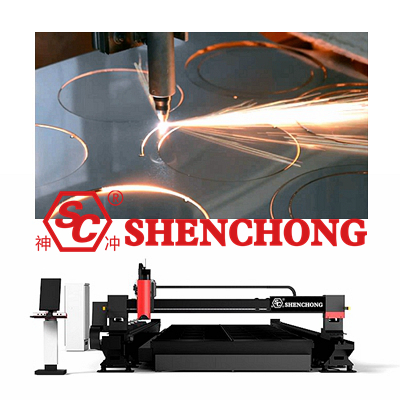

Laser cutting machine is a mechanical equipment used to cut metal and non-metal materials. It is cut by laser and has the advantages of high precision and fast speed, and is widely used. There are many laser cutting machine products on the market, so what models are there?

Generally speaking, there are many brands of laser cutting machines, and the representation methods for laser cutting machine models produced by different manufacturers vary. Generally, there are two main types of model representation methods:

There are various types such as 3015, 4015, 4020, 6020, 6025, 8025, 13025, etc. 3015 refers to a working format of 3000mm * 1500mm.

There are various options including 100w, 300w, 500w, 650w, 700w, 800w, 1000w, 2000w, 3000w, 4000w, 7200w, etc.

Different models of laser cutting machines have certain differences in performance, and there are generally eight main parameters for laser cutting machines:

The continuous cutting time of the laser beam at the current point is inversely proportional to the movement speed of the cutting head on the material plane. The higher the speed, the shorter the duration, and vice versa.

Sometimes, some geometric parameters can also affect the speed, such as when the time is similar, if the cutting space of the components is too small, it can lead to thermal accumulation of the material.

The laser beam is focused below the nozzle through a lens, with the highest power density at the focal point. Therefore, the height of the cutting head from the cutting surface not only affects the plane focusing area, but also affects the energy density at the current point.

Directly determines the power of the laser beam. When the ratio is 100%, the laser beam has the maximum power.

In addition to continuous laser beams, pulsed laser beams, which are continuously and quickly switched on and off, are also used. Adjust its power by adjusting its duty cycle to achieve some special functions.

The percentage of time that a pulse laser remains in an on state for one cycle is directly proportional to the laser power. When the duty cycle is 100%, that is, fully open within one cycle, it is continuous laser.

The laser power supply is divided into several parts to provide energy, and some are individually turned off when needed to reduce the power of the laser.

In order to match different cutting speeds, the laser power can be adjusted at any time by the transmission door equipment. For example, when the cutting direction changes, the translation speed of the cutting head will be lower than that of linear cutting.

If there is no real-time adjustment of power in this section, excessive energy release in the current section will affect the cutting quality. So it is necessary to use a modulator to reduce laser power to meet the needs of corner cutting.

Shoot out from the nozzle to protect the cutting head from smoke and dust, in order to improve cutting quality. Although this factor is not related to laser power and the duration of current point cutting, it is still an important factor for metal cutting. There are several different gases to choose from to meet the cutting needs of different materials.

The power of a laser cutting machine varies, and the thickness of the plate it can cut will also vary. A thin plate laser cutting machine is a device used to cut thin plates. So, what is the power of a thin plate laser cutting machine?

It is understood that thin plates generally refer to plates with a thickness of 0.2-4mm. Taking carbon steel plates as an example, cutting 0.2-4mm steel plates can be done using a 500W-1000W laser cutting machine, which can cut carbon steel plates with a thickness of 0.8-10mm.

Cutting plates of different thicknesses requires the use of laser cutting machines with different powers. Only by knowing how much power can be used to cut metal plates, can we better cut the plates and avoid wasting manpower and resources due to operational errors.

Below, we will talk about laser cutting machines with various powers and plate cutting:

1) 1000W cutting carbon steel thickness: 0.8-10mm; Cutting stainless steel thickness: 0.8-5mm; Aluminum alloy: 0.8-3mm; Brass: 1-3mm.

2) 1500W cutting carbon steel thickness: 1-16mm; Cutting stainless steel thickness: 1-6mm; Aluminum alloy: 1-4mm; Brass: 1-3mm.

3) 2000W cutting carbon steel thickness: 1-20mm; Cutting stainless steel thickness: 1-8mm; Aluminum alloy: 1-6mm; Brass: 1-5mm.

4) 3000W-3300W cutting carbon steel thickness: 1-22mm; Cutting stainless steel thickness: 1-10mm; Aluminum alloy: 1-8mm; Brass: 1-6mm.

5) 4000W cutting carbon steel thickness: 1-25mm; Cutting stainless steel thickness: 1-15mm; Aluminum alloy: 1-10mm; Brass: 1-8mm.

6) 6000W cutting carbon steel thickness: 1-30mm; Cutting stainless steel thickness: 1-20mm; Aluminum alloy: 1-20mm; Brass: 1-12mm.

7) 8000W cutting carbon steel thickness: 1-40mm; Cutting stainless steel thickness: 1-30mm; Aluminum alloy: 1-30mm; Brass: 1-16mm.

8) 10000W cutting carbon steel thickness: 1-45mm; Cutting stainless steel thickness: 1-40mm; Aluminum alloy: 1-40mm; Brass: 1-20mm.

9) 12000W cutting carbon steel thickness: 1-50mm; Cutting stainless steel thickness: 1-45mm; Aluminum alloy: 1-45mm; Brass: 1-20mm.

10) 15000W cutting carbon steel thickness: 1-60mm; Cutting stainless steel thickness: 1- 50mm; Aluminum alloy: 1-40mm; Brass: 1-20mm.

The above is a comparison between the power and plate thickness of laser cutting machines with different powers. There may be slight differences in actual situations, but the difference is not too far. Considering that the cutting incision may have slag to some extent, it is recommended to choose a machine with slightly higher power when choosing.