As an additive in the smelting industry, the shear efficiency of cobalt plates is particularly important. However, it is not uncommon for efficiency issues to affect production capacity. The fully automatic cobalt plate shear machine developed by Wuxi Shenchong can greatly improve cutting efficiency. Two hydraulic guillotine shearing machines can achieve a production capacity of 35 tons in 24 hours. Maximize the satisfaction of enterprise needs.

Cobalt plates cut into small pieces are added to various metal raw materials. Cobalt based alloys or cobalt containing alloy steels are used as important metal materials in gas turbine blades, impellers, ducts, jet engines, rocket engines, missile components, various high load heat-resistant components in chemical equipment, and the atomic energy industry.

With the continuous development of society, the demand for cobalt plates continues to increase. At present, the vast majority of shearing machines on the market are not suitable for cobalt plate cutting.

One main reason is that the cobalt plate is forged. The plate thickness is uneven. Traditional shearing machines are designed and manufactured for steel plates. When cutting cobalt plates, it is easy to encounter various problems such as oil leakage, rapid blade wear, and easy damage to the cutting machine.

The cutting of cobalt plates requires the use of high hardness and strength blades. The specific choice of shearing blade depends on the thickness, hardness, and cutting accuracy requirements of the cobalt cutting plate.

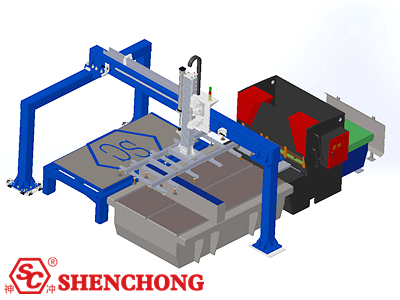

The fully automatic cobalt plate shearing machine developed by Wuxi Shenchong has been widely used in the cobalt plate industry, which can effectively improve cutting efficiency.

For plates with a thickness of 3-5mm and a length and width of less than 1 meter, we produce a special cobalt plate fully automatic shear machine with a thickness of 12X2500mm.

The oil pump and motor are equipped with a 40mm cutting machine. The Shenchong Cobalt Plate Shearing Machine can simultaneously achieve automatic feeding and cutting of four plates.

The suction cup adopts a sponge suction cup to ensure the stability of the suction plate. The front feeding platform is customized with 316 stainless steel to prevent contact between cobalt plates and metals other than stainless steel.

The cutting machine is equipped with a stainless steel chain conveyor belt and a waste box, which can classify finished materials and waste materials through forward and reverse rotation to prevent waste of cobalt materials.

A stacking device has been designed after the conveying device, which can be used to place cobalt strips on the second front feeding and shearing machine at the rear through suction cups, robots, or manual labor.

The second shearing machine is designed with a customized pushing groove, which can achieve the simultaneous cutting of over 40 pieces of material into blocks. Compared with manual labor, it greatly improves production efficiency and solves the problem of tailings being unable to be cut, eliminating waste of sheet metal.

The entire cobalt plate cutting production line is independently designed and manufactured by our company. More than 20 years of production experience in shearing and bending machines, and more than 10 years of previous experience in front-feeding shearing machine production to ensure product consistency and stability. It can achieve 24-hour continuous work, providing protection for enterprise production.