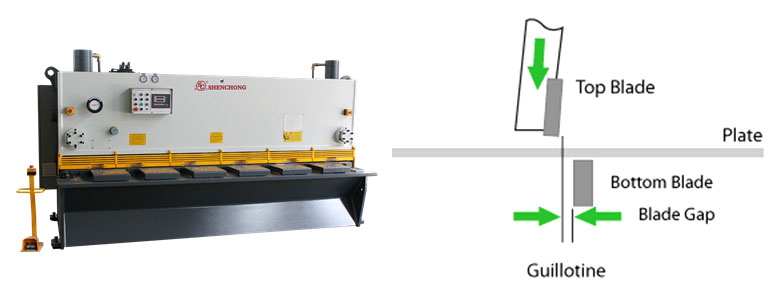

The hydraulic shear machine is a machine that uses a reasonable blade gap to apply a shearing force to metal sheets of various thicknesses by using a moving upper blade and a fixed lower blade to make the sheets break and separate according to the required size.

According to different working principles, they can be divided into hydraulic swing beam shearing machine and hydraulic guillotine shearing machine.

Hydraulic guillotine metal shear machines are often used in modern sheet metal processing production lines for ironworkers, because of its higher cutting accuracy, adjustable shear angle, longer blade life, longer oil cylinder life, and wider application range.

The guillotine shear metal sheet cutting machine makes a vertical linear movement to achieve a smaller degree of distortion and a more accurate straightness of the sheared material. In addition, the guillotine hydraulic plate shearing machine is not easy to deform because the oil cylinder, the knife beam, and the blade are in the same straight line and move perpendicular to the lower blade.

In 2017, Wuxi Shenchong successfully developed high-precision CNC hydraulic shear cutting machines and mass-produced them. The straightness of Shenchong hydraulic metal shear machine per meter is ±0.03MM, which can be used for laser tailor welding.

When cutting plates with a thickness of less than 20mm, the pendulum hydraulic punch and shear machine cannot adjust the cutting angle, so the cut material has twist-like distortion. The narrower the cut material, the greater the distortion.

The guillotine hydraulic shear machine can adjust the angle by adjusting the volume of the enclosed oil cavity of two oil cylinders in series:

– The shearing angle is enlarged and the shearing capacity is increased.

– The shearing angle is reduced, and the shearing speed is increased, saving electric energy and working time.

Wuxi Shenchong hydraulic shearing machine adopts the latest computer technology and has the characteristics of compact structure and complete functions. In addition to the controllable cutting angle, it can also control the backgauge stroke, blade clearance and cutting stroke.

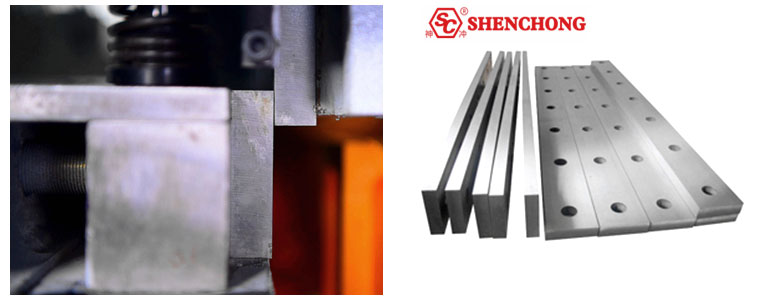

For swing beam shear cutting machine, its top blade cannot be used for 4-sided cutting, because the motion line of the knife body of the hydraulic swing beam metal cutting machine is arc-shaped. So only the blade can be used for two-sided cutting.

But for guillotine shear metal cutting machine, it moves up and down in a straight line, and can use rectangular blades with four-sided cutting edges, so the serving life of the hydraulic punch and shear cutting machine’s blades on the guillotine shearing machine is twice that of the pendulum type.

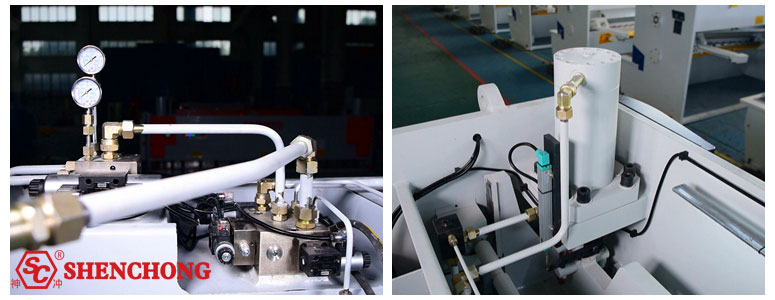

The built-in oil cylinder used in the pendulum hydraulic brake shear machine is difficult to lubricate and repair. However, the upper and lower chambers of the engineering oil cylinder used by the guillotine shears do not need additional lubrication, which greatly increases the service life.

The hydraulic oil cylinder of Wuxi Shenchong guillotine hydraulic shearing machine is made of 45# steel quenched and tempered, the inner hole is finely bored and extruded, and the inner surface has high strength.

The piston rod is also made of 45# steel quenched and tempered, and the surface is plated with nickel and phosphorus, which has self-lubricating function to increase wear resistance.

The guillotine metal shearing machine has a wider range of use, and can cut and process metal plates of different materials, such as carbon steel, stainless steel, and aluminum alloy, etc.

At the same time, because its metal cutting angle is adjustable, effective cutting can be achieved by adjusting the cutting angle for plates of different thicknesses.

All in all, when the equipment procurement cost is not considered, the Shenchong hydraulic metal shearing machine is more recommended, which has higher cutting accuracy and longer service life (for blade and oil cylinder), can meet more requirements of different materials and different thicknesses.

The overall work efficiency is higher for the sheet cutting work, and the return on equipment investment will be higher too for ironworker. Of course, if your requirement of shearing accuracy is not high and the shearing thickness is low than 16mm, the pendulum shears are still a good choice in terms of cost performance.