In the machinery manufacturing industry, the molding of many parts is inseparable, such as casting molding, machining molding, power press molding and press brake bending molding. In the stamping industry, two types of press mold forming and bending forming are more common. In production, if you can understand the advantages and disadvantages of each molding method, it will be of great help in the division of the process route and the preparation of the pre-production period. It will be able to analyze the molding method of each material and save more Production time and production cost. Here is a simple analysis of the advantages and disadvantages of press mould forming and bending forming.

1) The molding of various curved shapes can be completed by manufacturing molds:

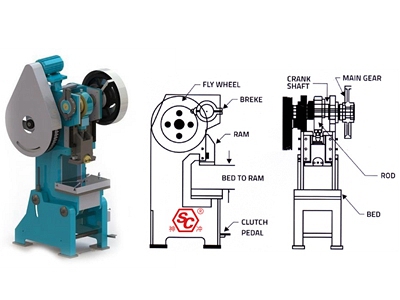

In manufacturing enterprises, a large number of presses are often used for production. As small as household products, the forming of pots and pans; as large as the production of high-end products such as automobiles, trains, ships, and airplanes. The front hoods of automobiles, the side wall panels of trains, and the wings of airplanes are mostly curved shapes, which are difficult to form. The press can be used to manufacture molds of various shapes according to the design requirements, and the mold is installed on the press, and the movement of the mold is driven by the up and down movement of the press slider to obtain the desired shape and complete the curved surface forming.

2) It can realize the forming, blanking and drawing production of smaller size materials.

The press can design convex and concave molds for different purposes according to different needs, so as to realize the tasks of forming, blanking and drawing.

When the press is formed, the upper and lower molds are engaged to complete the forming task of the material parts, and the production of small-size "B"-shaped parts and "cap"-shaped parts can be realized in production. It can also produce materials with shorter straight sections of arc edges, and can be formed at one time without increasing the lengthening to meet the technical requirements.

The press completes the production of punching, flanging and drawing by installing different specifications of concave and convex dies.

3) The production efficiency of the press is high:

When the press is used for molding, it is only necessary to install a suitable mold, and the pressure value and holding time are obtained through experiments, and then mass production of materials can be carried out. There are big differences, and the production efficiency is extremely high, which is suitable for the production of small varieties and large batches of materials.

- Single production and high manufacturing cost:

Manufacturing a mold can only produce one product, and the cost of manufacturing the mold is relatively high, each set of molds can be as little as tens of thousands of yuan, as many as hundreds of thousands of yuan, for some small batch production For big investment, the return is small, and the adaptability is not strong.

- High production cost:

In the process of manufacturing the mold, repeated trials and repeated modifications are required. During the debugging of the mold, a lot of raw materials will be wasted, and the materials after the mold may not fully meet the technical requirements. Some materials It requires subsequent manual adjustments to meet the requirements, which not only increases the cost of raw materials, but also increases the cost of manual adjustments.

- The production cycle is long, not suitable for the remodeling and upgrading of new products:

In production, no matter what is manufactured, remodeling and upgrading, improving the competitiveness of products is an indispensable process. Then a set of molds needs to be re-produced every time a part is changed. This not only has high mold manufacturing costs, but also greatly increases the production cycle, making it difficult to meet contemporary fast-paced production requirements.

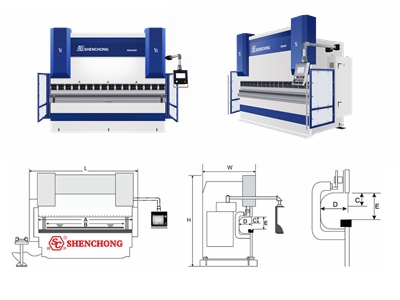

- The bending machine is suitable for the production of small batches of multiple varieties of materials:

The bending machine can achieve multiple uses in one tire. The use of one mold combination to complete the production of multiple materials has strong applicability, especially in the manufacturing and production of train bogies.

- The manufacturing cost of bending molds is low, and the life of each set of molds is very long:

The cost of each set of bending molds is only a few thousand yuan, and the manufacturing is simple, without repeated experiments, and each set of new molds can be manufactured directly. in production. The bending mold wears very little without being damaged, and each mold can be used for at least 10 years, which greatly saves the manufacturing cost of the mold.

- The bending machine can complete the production of "S" and "U"-shaped parts:

Those who are familiar with stamping and forming know that the "U"-shaped forming is the most difficult. If a press is used for forming, a certain degree of mold manufacturing is required. The amount of springback. The concave mold designed in this way needs a small mouth and a large bottom, while the punch has a big head and a small end. In this way, the convex and concave molds cannot be matched together. If there is no springback, the produced product will not meet the technical requirements. And it is difficult to repair, the use of bending machine for multiple molding can solve this problem, so as to achieve the production of "U"-shaped parts.

- The bending machine can be better adapted to the trial production of new products without any additional cost:

For bending production, one tire has always been the advantage of bending production. No matter how the shape changes, apply a set of tires. According to the size requirements of the template or drawing, the production tasks of materials of different sizes and different angles can be completed.

- The bending machine can complete a variety of polygonal shapes with different heights.

The forming of the bending machine can complete the multi-knife production of different side heights by turning over the material and setting the angle.

- The bending machine has a deflection compensation function:

When bending a long workpiece, due to the longer material, there will be a certain deviation in the forming angle between the middle position and the two sides, which will cause a large difference in the local position angle , The bending machine can adjust the angle of each position by adjusting the deflection compensation value, so that the bent parts are in a straight line, without manual secondary adjustment, which makes the production of long parts simpler and reduces labor strength, shorten production time and improve product quality.

Learn more about CNC Hydraulic Press Brake Machine

- There are certain requirements for the thickness of the material.

Generally, the thickness of the material to be bent does not exceed 50mm, and the thickness of the material exceeding 50mm requires greater bending force.

- It is easy to fracturing the material during the bending and forming process:

During the bending process, because the material is cut and cut, burrs or oxide layers will be generated at the corners and corners, which will easily cause the material to be bent. The parts appear to be cracked or broken, and it is difficult to guarantee the quality of the product.

- Large indentation occurs when some materials are bent:

Indentation is the most common problem that affects product quality in bending molding, because the selected bending mold is inappropriate or the material must use the required mold combination , It is inevitable to produce certain indentation, so it is necessary to increase the polishing process, and the thickness of the polished material needs to be tested. Some materials will be scrapped due to the deep indentation, thereby increasing the cost.

- When bending and forming, some materials will have slipping phenomenon, and the bent part cannot be turned up:

For square materials, there will be no failure to turn up, but for the forming of some irregular materials It is easy to cause the material to turn over, causing the material to fail to meet the process standard.

Combining the advantages and disadvantages of the above-mentioned power press molding and press brake bending molding, it is easy to define the molding method of the material when analyzing the molding method of the material, reduce the scrap rate of the material, save the production cycle time, reduce the production cost, and reduce the mold manufacturing Cost, thereby bringing higher benefits to the enterprise.