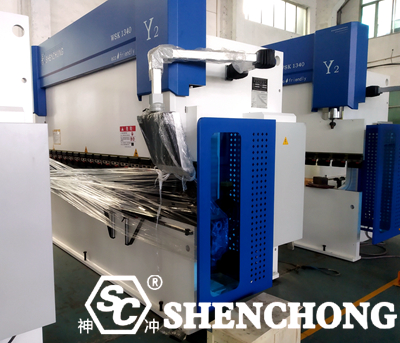

The WSK CNC Press Brake Machine is a high-precision bending equipment that combines CNC technology with an electro-hydraulic servo system and is widely used in the forming of metal sheets.

1. Machine Model

- SC-WSK series

- 130Ton 4000mm

- EL 15T CNC Controller

- 4+1 Axis

2. Working Principle

The core of the electro-hydraulic servo CNC hydraulic press brake machine is to control the movement of the oil cylinder through the electro-hydraulic servo system, driving the upper or lower die of the bending machine to accurately bend the plate. The CNC system will adjust the bending force and position according to the pre-set program and parameters (such as bending angle, plate thickness, material, etc.).

3. Main components

CNC system:

It is the "brain" of the entire bending machine, responsible for controlling the parameters of the bending process, mold position, bending angle, etc.

Electro-hydraulic servo system:

The hydraulic system is controlled by a motor to achieve precise bending force output and position control. The electro-hydraulic servo system has the characteristics of high precision and fast response speed.

Cylinder and hydraulic system:

The cylinder provides power for the bending action, while the hydraulic system is responsible for the transmission and control of oil pressure.

Bending die:

The upper die and the lower die are used to directly apply force to the sheet to complete the bending operation. The shape and material of the die will affect the final bending effect.

4. Features and advantages

High precision:

Due to the use of electro-hydraulic servo control, the WSK cnc press brake can achieve high-precision bending control with an accuracy of ±0.01mm.

Good stability:

The electro-hydraulic servo system can automatically adjust the hydraulic pressure according to the actual situation to ensure stable pressure throughout the bending process.

Energy saving and environmental protection:

Electro-hydraulic servo technology consumes less energy than traditional hydraulic systems because energy is consumed only when performing actions.

Easy operation:

Through the visual operation interface of the CNC system, the operator can easily set and modify the processing parameters, reducing the complexity of the operation.

High flexibility:

It can adapt to a variety of materials and plates of different thicknesses, suitable for the production needs of multiple varieties and small batches.

Electro-hydraulic servo CNC press brake machines are widely used in automobile manufacturing, aerospace, household appliances, construction industry and other metal processing fields. It is suitable for precision processing of various metal materials, especially in workpieces that require multiple complex bending.

SC WSK CNC press brake machine greatly improves the processing efficiency, precision and stability through the combination of advanced electro-hydraulic servo technology and CNC system, while also reducing energy consumption. It is an important equipment in the modern metal processing industry.