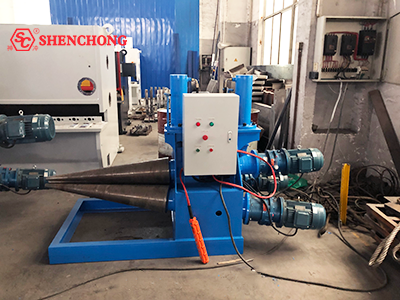

The three rollers are all conical rollers, the position of the two lower rollers is fixed, the upper roller is hydraulically lifted, and the three rollers are the main driving rollers. It is specially designed to roll conical workpieces, and it is controlled centrally by the operating handle. SHENCHONG 3 roll cone bending machine is mainly used to bend a certain thickness of metal plate into a cone at normal temperature, and its working principle is rotary bending deformation.

You may also want to check our other 3 Roller Plate Rolling Machine and 4 Roller Plate Bending Machine.

(1) Upper and lower rollers: It is an important part of the plate rolling machine. The roller surface is conical, the material is high-quality forgings, and it is quenched and tempered.

(2) Frame: steel plate welded structure, removing welding stres. At the top of the frame is equipped with an upper roller pressing oil cylinder, the piston rod of the oil cylinder is connected with the bearing seats of the upper roller. The upper roller moves up and down with the oil cylinder.

(3) Main transmission device: The three rollers of this machine are all driving rollers, which are composed of main motor, cycloidal pinwheel reducer and so on. It can rotate forward and reverse to provide power for sheet rolling.

(4) Electrical part: The electrical appliances of this machine are all installed in the electrical box, which is operated by the handle, convenient to operate. The main circuit adopts three-phase 380V alternating current. 3 main motors drive the work rolls to rotate, and 1 motor drives the hydraulic pump station with short circuit overcurrent protection.

(1) Main drive: The three rollers of this machine are all driving rollers, which are composed of three main motors, cycloid reducers, etc. It can rotate forward and reverse to provide power for sheet rolling.

(2) Auxiliary transmission: drive the upper roller to up or down through the hydraulic cylinder.

The feeding of the metal plate is driven by the friction between the metal plate and the work roll. According to the arc formed by the three tangent points between the metal plate and the work roll, the plate is bent into an arc, The required radius of curvature of the arc can be achieved by adjusting the inclination and lifting of the upper roller.

(1) When rolling: first make the distance between the lower busbar of the upper roller and the upper busbar of the lower roller greater than thickness of the plate, then press well the head of the fan-shaped plate, centered and symmetrically placed on the lower roller, which is the basic working position, Gradually press down the two cylinders (note: the pressure is not synchronous),Operating the rollers rotation(Align the rotation direction with the feed direction), Bend the middle of the sheet according to the radius of curvature, Correspondingly adjust the inclination and lifting of the upper roller, Repeat the forward and reverse rolling several times until the mouth is closed.

The position of the upper roller and downward need to be mastered by rich rolling experience.

(2) Unloading: Raise the upper roller to a certain height, and the rolled workpiece can be unloaded from one end of the upper roller, and the unloading work is completed.

(3) Note: Before rolling, we should clean up the sheet oxide slag, and do not make the upper and lower rollers squeeze each other. Excessive pressure will easily cause the rollers to break.

If the fan-shaped plate placed asymmetrically on the roller, it is easy to cause misalignment and wrong sides when closing. Improper adjustment of the upper roller will easily cause the small or large mouth to be connected first. The specific operation requires experience,it is best that experience operators to test and operate machine.

If pre-bent fan-shaped plate not pre-bent, it is necessary to roll two sides of the plate firstly, then roll the central to ensure that both sides of the weld are straight, finally correct it on the plate rolling machine after welding.

As the experienced rolls plate bending machine factory, Shenchong exported 3 rolls plate bending machine to more than 70 countries globally over 20 years. We have different models of 3 rolls sheet metal bending machine for sale, contact us today!

Q: How to get a 3-roll plate rolling machine quotation from SHENCHONG?

A: Every customer can get direct sheet metal plate 3 rollers rolling machine price from us. Shenchong is one of the largest plate bending rolls suppliers, and we can offer you detailed technical proposal and price. Please provide us your plate material type, max thickness and max width. Also, it will be helpful if you can send us your workpiece drawings or related rolling requirements.

Q: What’s the shipping cost from China to your country?

A: We can send machine to your port or door address by sea or rail, and so please kindly tell us your nearest port. We have reliable shipping agent to insure the safe convenient and time delivery.

Q: Do you accept LC payment?

A: Yes, normally our payment is 30%+70% T/T, LC payment is also acceptable. Our plate bending roll machine price is affordable, contact with us today!

Q: Do you have installation and training service?

A: Yes, Shenchong is a reliable China plate roll bending manufacturers with full exporting experiences. Installation Services are available with all our machines. We dispatch technician to customer's factory for installation and pre-operation of machines. (Customers only need to pay the airfare and hotel)

We provide detailed machine user manuals and train videos, or customers can set a video call with our sales and engineers. Our technician is available to your factory and offer training of how to use our machines. The buyer needs to afford plane tickets. As well, you may send your technician to our company to learn how to operate machines.