Copper is a common metal with good conductivity and thermal conductivity. In addition, copper also has a high shear force. Shear force refers to the ability of an object to undergo shear deformation when subjected to cutting force. The magnitude of shear force depends on the material and shape of the object. At room temperature, copper has a high shear force and can be used to manufacture parts and tools that require high shear force.

However, at high temperatures, the shear force of copper will be greatly reduced, because at high temperatures, the molecular energy of copper increases, making it prone to plastic deformation, thereby reducing the shear force. Therefore, when selecting materials, different materials should be selected based on the actual application situation to achieve the best performance and effect.

As is well known, laser cutting machines use high-power density laser beams to irradiate materials, quickly heating them to a molten or vaporized state. As the beam moves the material, narrow slits or welds are formed. Laser processing has high efficiency, high energy density, and flexibility, making it the best choice for various industries in terms of accuracy, speed, and efficiency.

So what is high reflectivity material? Many types of laser technology are affected by their inherent sensitivity to retrogressive light, leading to unstable operation and destructive automatic shutdown during the processing, and even causing significant damage to the laser, invisibly shortening its lifespan. Cutting high reflective materials with metal laser cutting machines is an important challenge for many metal laser cutting machine manufacturers nowadays. High reflective metal materials have always been difficult to cut by metal laser cutting machines, including copper, aluminum, gold, etc. These materials are also common materials in our daily processing.

Nitrogen is an auxiliary gas for improving cutting efficiency in laser cutting equipment. For copper materials below 1mm, it is completely possible to use a metal laser cutting machine for processing. When the thickness of copper metal reaches 2MM, it is impossible to process using only nitrogen gas. At this time, oxygen must be added to oxidize it in order to achieve cutting.

Copper plate shearing machines are widely used in the non-ferrous metal processing industry, steel industry, steel structure industry, building materials industry, shipbuilding industry, automotive industry, scrap steel recycling and other metal shearing industries.

Wuxi Shenchong shearing machine is synonymous with high-precision shearing. The fully CNC high-precision shearing machine adopts the German ELGO CNC system, and the accumulator returns smoothly and quickly. The straightness of the cutting board reaches ± 0.03mm/m, and the straightness of the cutting board can be adjusted. The board can be used for laser welding. Has strong rigidity and good cutting accuracy, with a minimum shear thickness of 0.2mm. CNC controls the cutting length, cutting width, cutting thickness, and cutting angle. Its cutting accuracy is higher than that of laser cutting and CNC punching machine cutting.

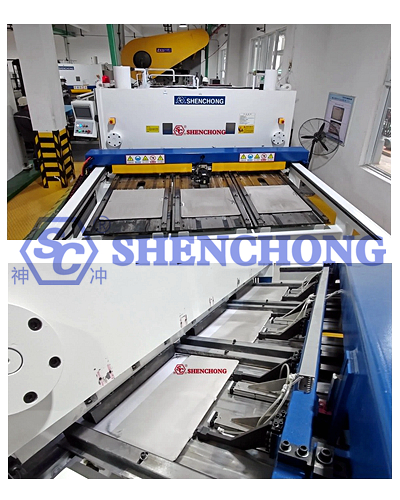

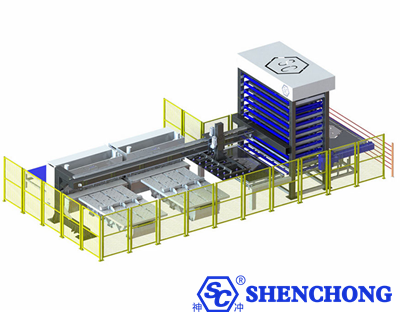

The fully automatic cutting unit developed by Wuxi Shenchong Company effectively solves the problem of copper plates that cannot be produced using laser cutting machines.

Copper plates, as cast plates, often cause headaches for production managers due to the cutting process during the production process. Both shearing machines and CNC punching machines are designed for traditional cold-rolled and hot-rolled plates. Copper plates are not suitable for traditional methods of cutting or punching due to their uneven surface. When shearing cobalt nickel copper with shearing machines and CNC punching, problems such as high failure rate, insufficient reliability, and low production efficiency are prone to occur.

In response to customer issues, the fully automatic cutting unit developed by Wuxi Shenchong Company can effectively solve the above problems.

This unit adopts a single beam truss suction cup feeding method, and the sheet metal is cut to a fixed length by a front feeding shearing machine. To adapt to the special characteristics of the board, our company has changed the traditional clamp to a push head and added a rear stopper to meet the high-strength usage needs of customers. The pressure foot oil cylinder of the shearing machine has been changed to a pressure beam to solve the problem of uneven plate material that cannot be pressed. The distance between the pressure beam and the blade is specially customized to meet the minimum cutting requirement of 40mm, ensuring that the last blade is cut in place without wasting raw materials. The rear is equipped with a chain plate transmission line that can rotate forward and backward. The first blade first cuts the waste material and then reverses it into the waste bin, followed by forward cutting. The waste bin is easy to extract for secondary use.

The cut strip is leveled by a reverse torsion device, and then enters the leveling machine for secondary leveling through a material tapping device to ensure that the strip is not twisted or arched, and does not affect subsequent cutting blocks.

The leveled strip material is placed on the second front feeding shearing machine by a handling robot. The front feeding platform has a customized guide groove, and the maximum size of the shearing machine can be 40mm, which can meet the cutting of 15 or 20mm nickel plates. Customized guide groove pushing ensures cutting speed and stability. The rear discharge platform can be directly connected to the finished product box by a chain plate wire. The finished product box is equipped with a weighing device and consists of three rotating platforms for the finished product box, ensuring that the next finished product box rotates and connects after the finished product is loaded to the specified weight, and the machine does not stop, maximizing production efficiency.

Finally, whether to choose a fully automatic cutting production line unit or a laser cutting machine depends on the actual production.